2wpuller

letting the smoke fly

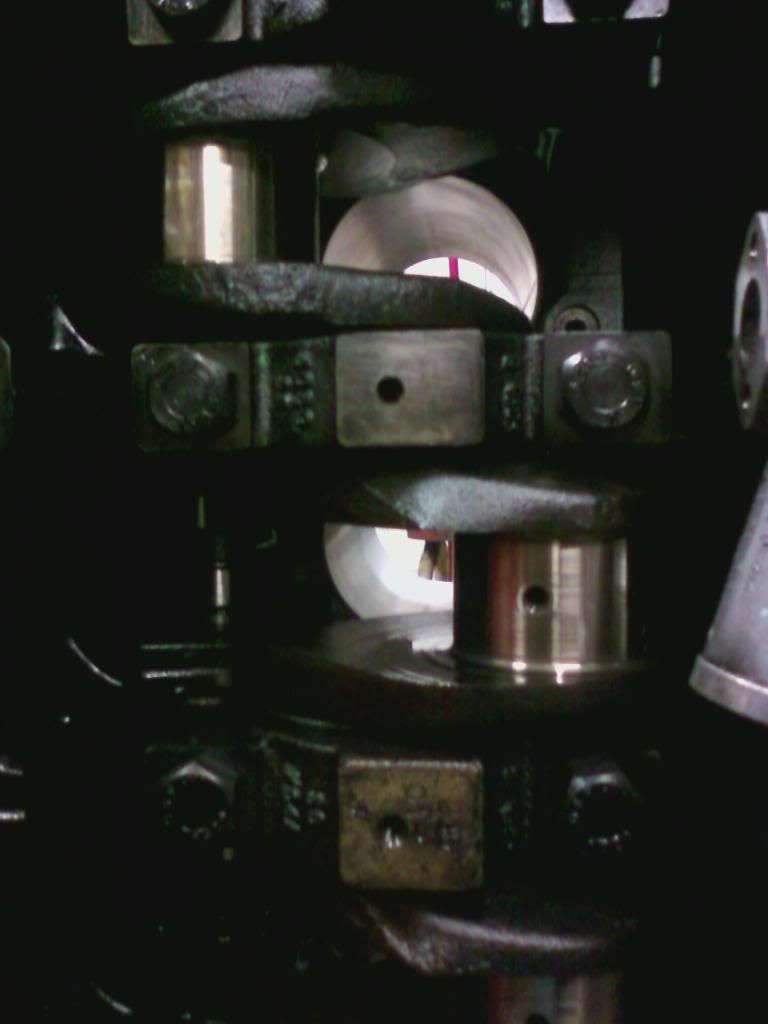

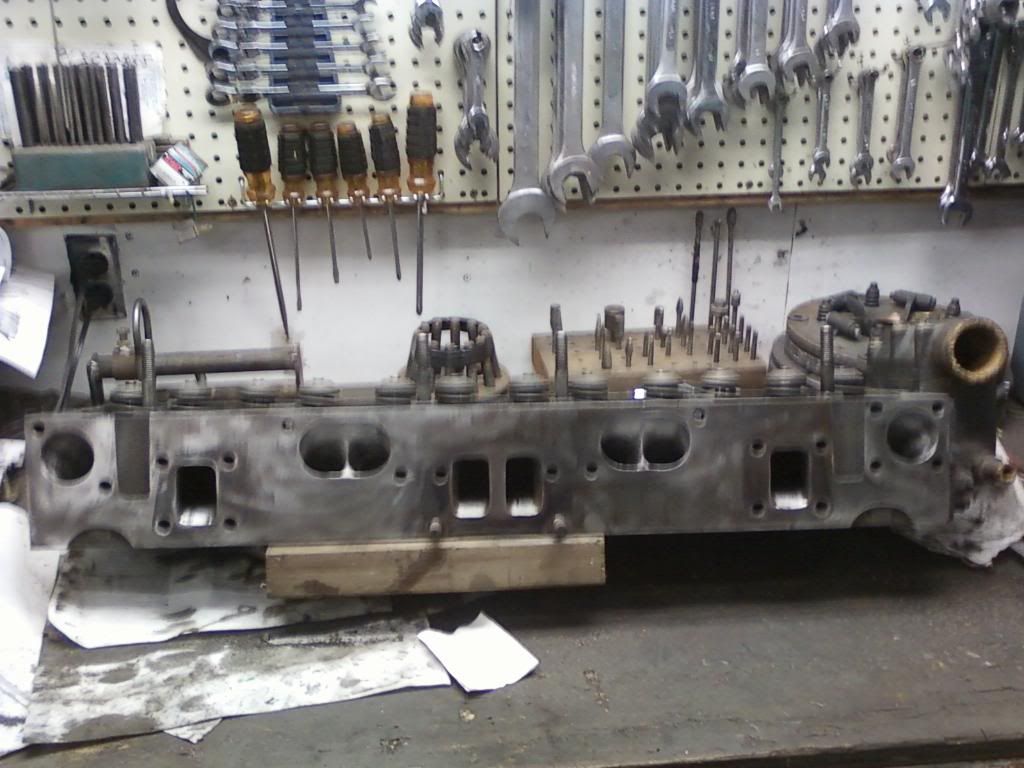

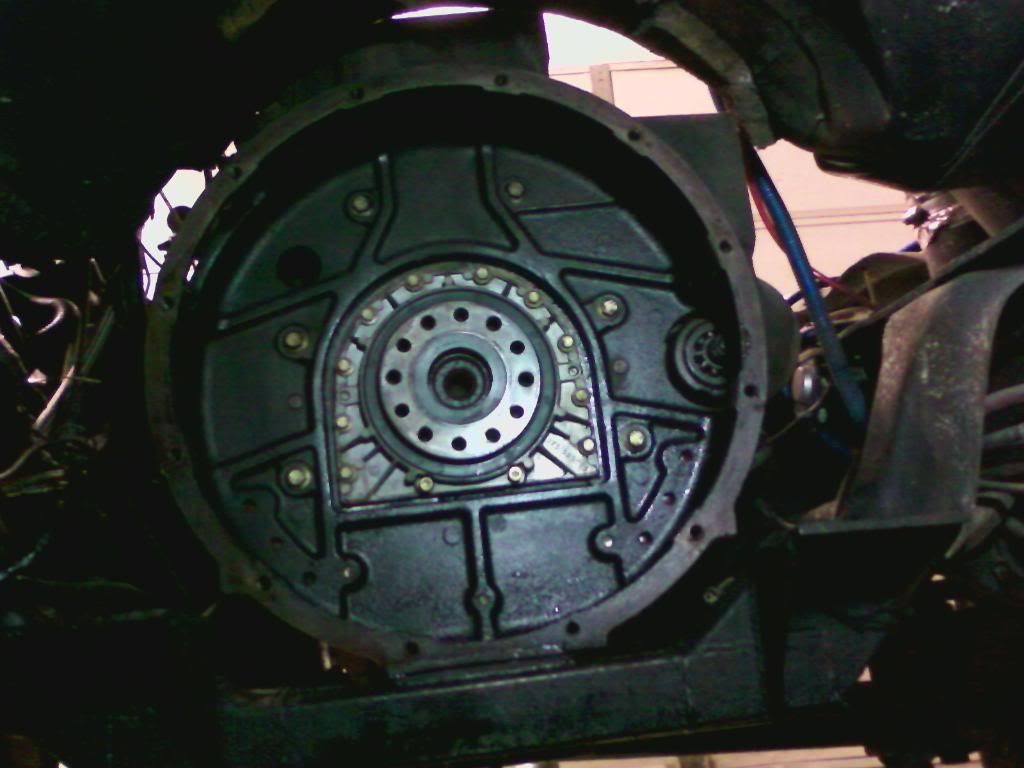

I have gotten old and lazy Sold the RTO6610 eaton out of my 75 Ford and putting in a 1000 allison out of a 06 chevy.While everything is apart desided to see why the motor had soo much blowby had it for along time.A few guy's kept saying it was a head gasket.Time to pull it all down and find out.

Dale

Dale