I am trying to get my head around how a twin turbocharger setup works, mathematically, especially when there is a big mismatch between the two turbochargers.

A certain company is promoting the use of an Aurora 7500 (apparently capable of 135 pounds/minute) over top of a stock HE351VE on a Cummins 6.7 as a super all round turbo charger setup. Suitable for every day driving, towing, pulling, etc.

I'm looking for factual, technical information to prove or disprove these claims.

First of all, what model of turbocharger is an Aurora 7500 turbo based on ? Is a compressor map available ?

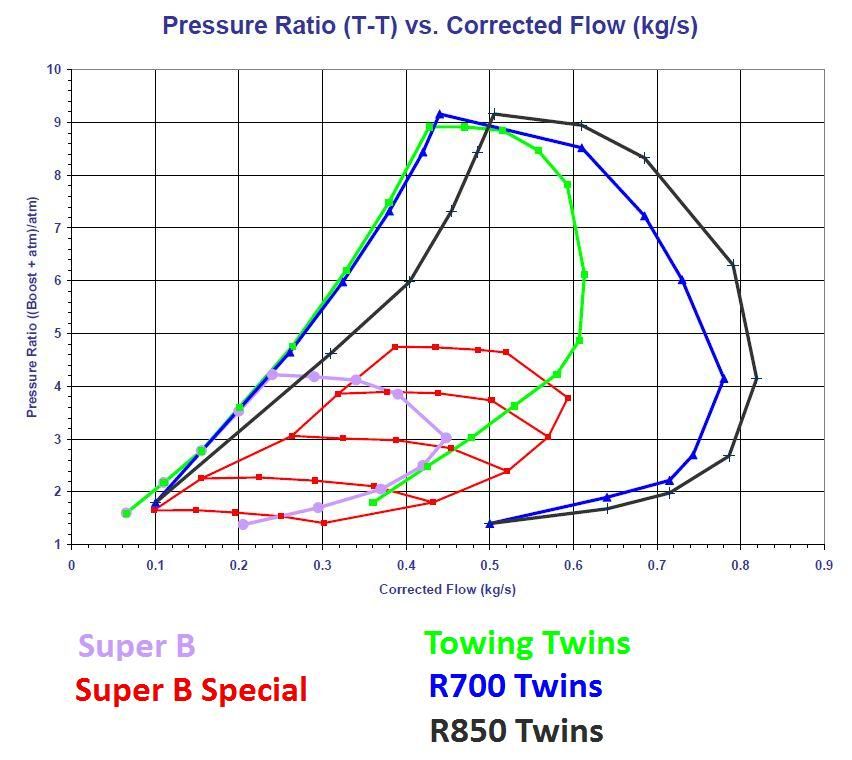

How do surge limits work with twin turbos ? One of the problems with a big single turbo is that it will surge at low mass flows (read low RPMs) and high boost pressure. How does this work with twins ?

In the case of the A7500, it supposedly has a maximum flow rate of 130 lbs/minute. A Cummins 6.7 at 1600 RPM and 30 PSI of boost is flowing about 30 pounds per minute. Wouldn't the A7500 be pretty much stalled or freewheeling at that flow rate ?

Then we get to spool ups. How does spool up work with twins ?

Something I don't understand is how someone can claim that a twin setup can spool as fast as a stock single turbo. The same engine exhaust flow is now split between (over) two turbines, so each turbine is only getting half the exhaust energy. And the compressor on the A7500 is massive. How does a twins setup overcome this ?

Then we get to airflow matching. The HE351 has a maximum airflow within its map of less than 60 lbs per minute. The A7500 has an air flow of 130 pounds per minute. How can a turbocharger rated at 60 pounds per minute efficiently feed a turbocharger moving 130 pounds per minute ?

I'm not saying that all these claims are wrong, only that I am not understanding the principles at play.

Thanks in advance for the help.

A certain company is promoting the use of an Aurora 7500 (apparently capable of 135 pounds/minute) over top of a stock HE351VE on a Cummins 6.7 as a super all round turbo charger setup. Suitable for every day driving, towing, pulling, etc.

I'm looking for factual, technical information to prove or disprove these claims.

First of all, what model of turbocharger is an Aurora 7500 turbo based on ? Is a compressor map available ?

How do surge limits work with twin turbos ? One of the problems with a big single turbo is that it will surge at low mass flows (read low RPMs) and high boost pressure. How does this work with twins ?

In the case of the A7500, it supposedly has a maximum flow rate of 130 lbs/minute. A Cummins 6.7 at 1600 RPM and 30 PSI of boost is flowing about 30 pounds per minute. Wouldn't the A7500 be pretty much stalled or freewheeling at that flow rate ?

Then we get to spool ups. How does spool up work with twins ?

Something I don't understand is how someone can claim that a twin setup can spool as fast as a stock single turbo. The same engine exhaust flow is now split between (over) two turbines, so each turbine is only getting half the exhaust energy. And the compressor on the A7500 is massive. How does a twins setup overcome this ?

Then we get to airflow matching. The HE351 has a maximum airflow within its map of less than 60 lbs per minute. The A7500 has an air flow of 130 pounds per minute. How can a turbocharger rated at 60 pounds per minute efficiently feed a turbocharger moving 130 pounds per minute ?

I'm not saying that all these claims are wrong, only that I am not understanding the principles at play.

Thanks in advance for the help.