Opie

Ingenuity Director

- Joined

- Apr 24, 2006

- Messages

- 363

Jim Fulmer said:We ran into the valve issue a few years ago, seems that the head would not flow enough for it to matter, the only other thing we did was cut the valves 45/45 and they actually wanted to go further. On the head porting he drilled two holes in the plenum on either end to allow access to #1 and #6, after the porting was finished he threaded plugs in the holes.

Jim

We? Do you by chance have the flow numbers? I have some valves that appear to be cut at 45/45 they are out of what was reffered to as a stage 2 head. I disagree with the 45 degree angle cut but have no real world data to back it up yet.

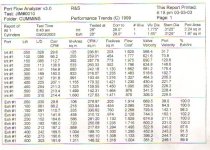

As mentioned earlier I have been doing research on things like making a 1.600 valve for the intakes in leu of the 1.300, enhanced unshrouding of the valve, merit/costs of doing a 5 angle vs 3 angle grind. However the next thing to happen, even though all casting marks in the air ports are obviously removed, polishing and glassbeading is going to be done in the attempts to help assist airflow speed some. On my 24V there is no way one could open the #6 restriction enough to make a significant difference by blind porting. Its just a dumb casting design. I know Budda power and J&H both have done similar on the plenum idea as I am finally doing right now.

Chris are you trying to hurt my feelings or something? lol The pushrod tubes are a 1.5 thou press, (they are .0015 bigger in diameter than the cavity they where installed in.) sure they slide in after soaking for two minutes in liquid nitrogen but I guarantee you they aint falling out. I didn't get to close to any water jackets, I have a head that sooner or later will be cut in half and plan on sending it to RIPS show room so people can see how much material they have to work with. But I had no problem finding out that info with visual checks of the open water jackets and a piece of 14 guage solid wire.