NakeDiesel

Smoke'n in the Mud

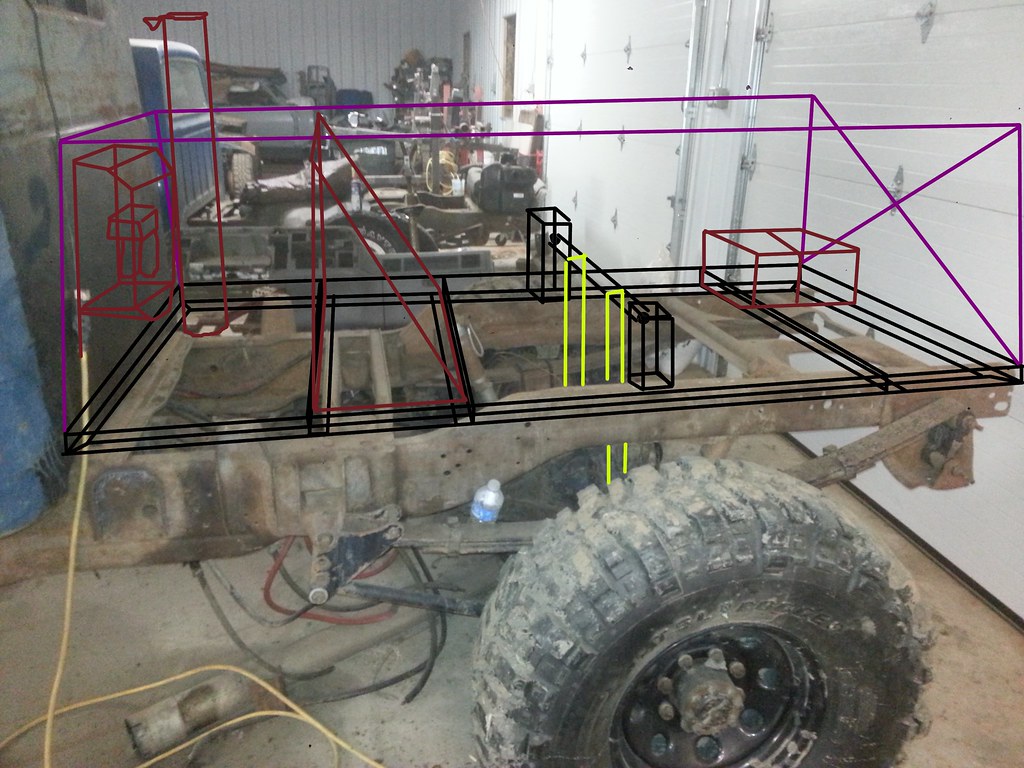

They had a longer nose, but I love the look of the old 46 power wagon more and I picked up the body for my ff pw for 500.00 a couple of years ago. I like the old flat fenders on the truck and the narrow nose. If I was making a streetable truck, it would be a different story, but this truck will never see the street in it's present form. The biggest reason I'm reboding the truck is to reduce the weight of the truck.