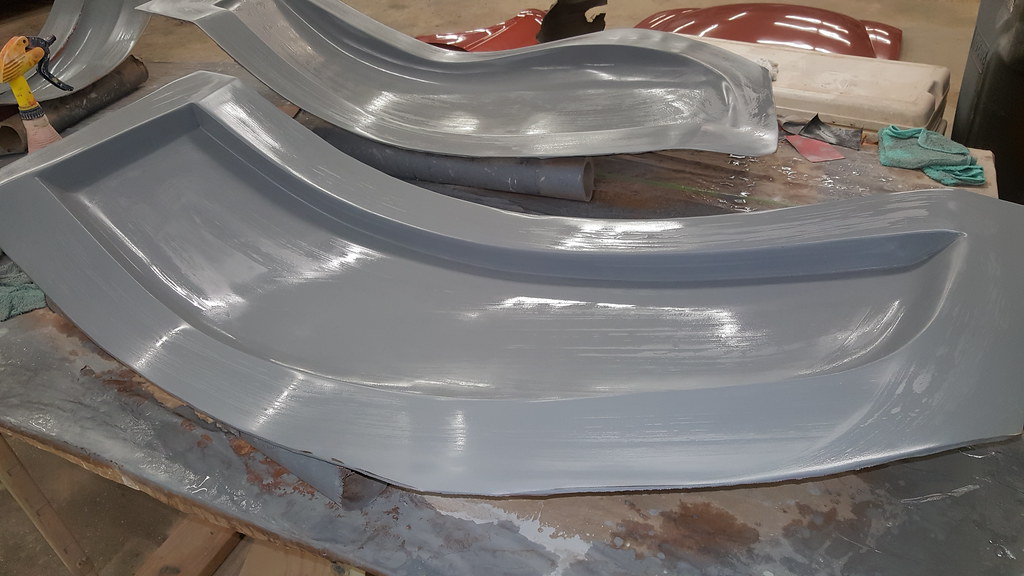

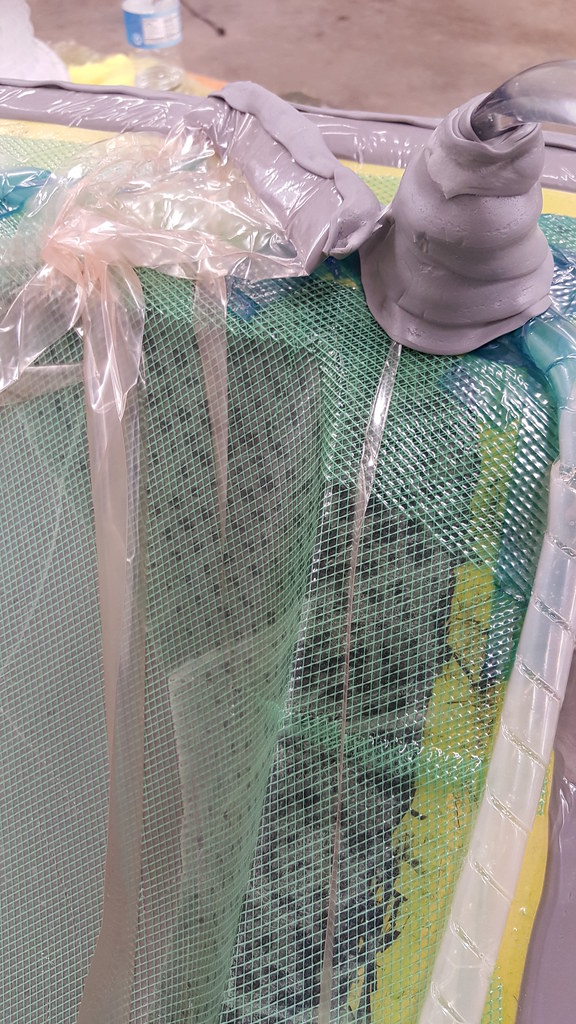

Busy freaking weekend. Friday picked up our Tshirts, Coozies and Stickers and talked to Scott about making me a wrap for the center of the grill. Think it will turn out great. Also started making CF parts friday. I got the first rear fender made that night. Saturday, I did the color run with my wife that morning, 3.1 miles I think, I let her set the pace and we walked with a bit of running. Then it was home and out to the shop where I got one of the front fenders setup and the second front fender cut out. I got the epoxy into the first front fender Sat night and today I got the epoxy into the 2nd front fender and started prepping the rear fender mold to make the 2nd rear fender. I've been learning a lot as I go on these and each one seems to turn out a little better or work better. Still fighting vacuum leaks, even resorted to using a stethoscope to try and find them...

Today, my wife helped me out and cleaned up on the inside of the cab, it's looking much better. She's 5'5" tall and couldn't believe I could get in and out of the cab at 6' 4" tall. Cleaned up the edges of the one rear fender and marked and drilled holes in it to put it on the truck and mark where to trim the ends up at and then I can get the edges sanded.

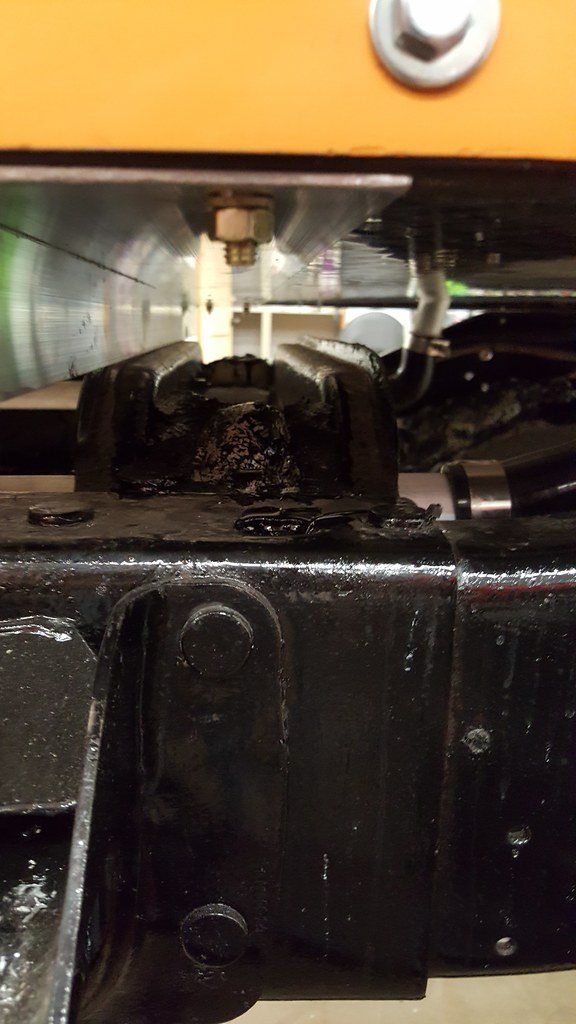

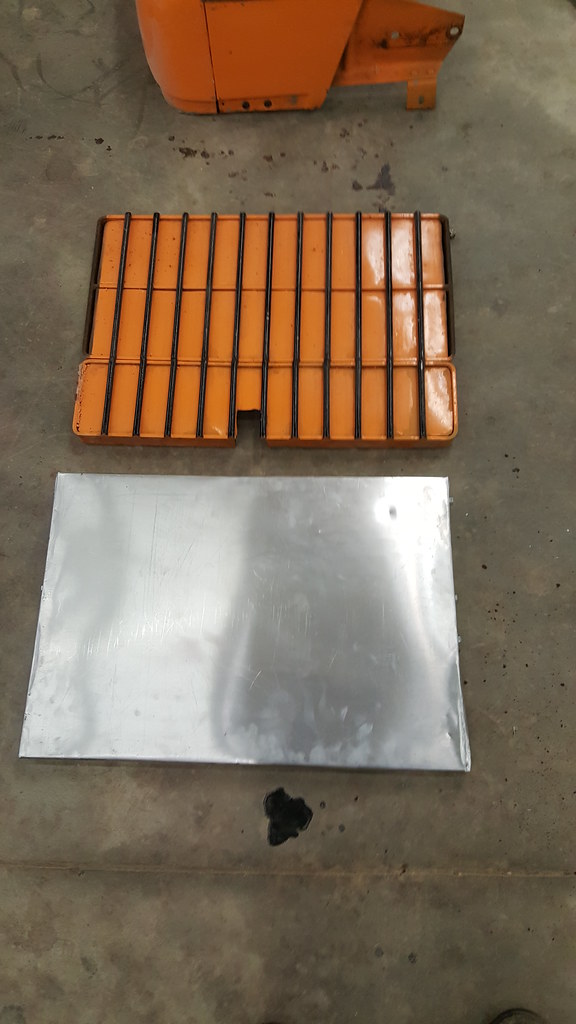

Also cleaned up the grill outer shell on the inside and outside and started putting it on the truck. Cleaned up the inside of the hood, one side was covered in mud and the other side a nice black mud/soot coating. Broke out my little sheet metal brake and bent 2 ends of the new cover for the enter section, need to get it on lighter frame and clamp those two ends on still and then bend the two shorter sides.

Coozies and stickers

checking for air leaks

Figured out I need a different type of tubing, this stuff collapses too easy

Some new wall art

Rear fender, not perfect by any means, had a dry spot in it that I think I've fixed, think it will work though

Laying out front fender

https://c1.staticflickr.com/3/2893/33785615992_aee8acdd48_b.jpg[/img

[img]https://c1.staticflickr.com/3/2938/33812902751_5f9097a132_b.jpg

2nd front fender

Trying rear fender on

grill on the truck

cleaned up hood