You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

steed speed exhaust manifold or stainless

- Thread starter 97rada

- Start date

Bump for compound guys answer.Anyone with twins using the straight t4 had to do anything to the hot pipe or bottom turbo mount so it will fit properly?

Bponci

rookie

- Joined

- Sep 15, 2006

- Messages

- 2,160

If your hot pipe is on a fixed flange it will index it closer and lower tword the block. If you have a v-band style you can reindex it and shorten the primary flange side to raise it back up. You will also need to redo the lower turbo support. If you deal your cards right your cold pipe may be closer than you would think. These are just some differences you will encounter.

Thank you!If your hot pipe is on a fixed flange it will index it closer and lower tword the block. If you have a v-band style you can reindex it and shorten the primary flange side to raise it back up. You will also need to redo the lower turbo support. If you deal your cards right your cold pipe may be closer than you would think. These are just some differences you will encounter.

Read post# 123, it answers your question.Is anyone running a straight flange with twins on a 2nd gen? can't find info or pics anywhere!?

Bersaglieri

Ron Swanson's Brother

- Joined

- Jan 8, 2008

- Messages

- 1,957

We had the same problem. Argued with Johnny over it and he eventually took the manifolds back and refunded the cost, we ate the shipping.

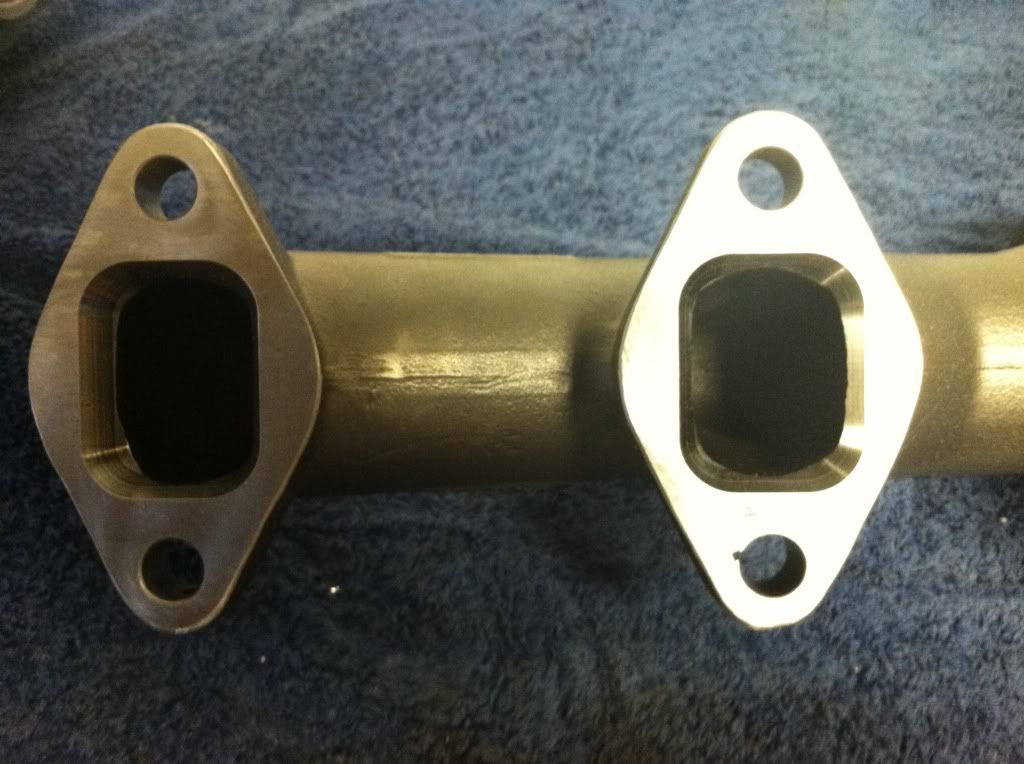

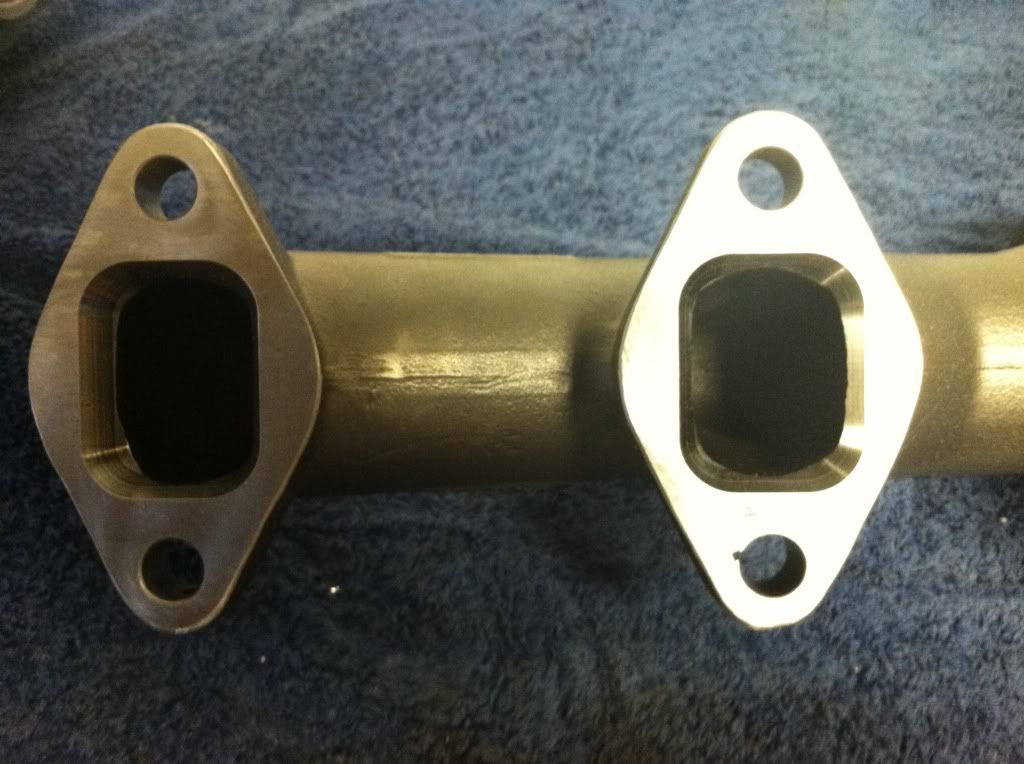

The Stainless manifolds are cast incorrectly making for a .150" port mismatch between the center two ports and the holes are drilled off by .100" to try and center the bolt holes on the flanges to the eye.

The part that was frustrating was the attitude that nothing was wrong, that other people don't measure the parts and just crossthread their manifold bolts into the head so why don't we?

The Steed manifolds are great. Steed communication is excellent.

I'm looking at manifolds and if this is the case, I'm surprised people are still buying Stainless manifolds. Was this a 12v, 24v, or CR manifold casting?

Anyone want to sell their used Steed? :Cheer:

I'm cheap so I'm trying to justify dropping my ported stock manifold, skipping the 3 piece, and going to the Steed. My biggest need is EGT reduction and spool up. Oh and has to flip/space correctly for the compounds.

-Dustin-

Last edited:

9812valveguy

New member

- Joined

- Oct 24, 2011

- Messages

- 25

Stainless diesel T3

Kind of surprised that with all the talk so few pics were posted.

Here's a few pics of mine.

Kind of surprised that with all the talk so few pics were posted.

Here's a few pics of mine.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

Didn't get to my first post to edit it soon enough.

I'm not saying hardware not included would make me decide one way or another. Just pointing that out for anyone who might be concerned. I'd probably go the stud route anyhow.

However, Stainless does admit that it will turn blue after you've run it hard. Not sure if I'd buy one just to have it turn blue.

Steed is pretty much taking the cake in this thread and they are some b!tchin looking manifolds. I think I'd end up going with one when the time comes. I love threads like these that can provide real data and honest reviews of products.

I'm not saying hardware not included would make me decide one way or another. Just pointing that out for anyone who might be concerned. I'd probably go the stud route anyhow.

However, Stainless does admit that it will turn blue after you've run it hard. Not sure if I'd buy one just to have it turn blue.

Steed is pretty much taking the cake in this thread and they are some b!tchin looking manifolds. I think I'd end up going with one when the time comes. I love threads like these that can provide real data and honest reviews of products.

Last edited:

9812valveguy

New member

- Joined

- Oct 24, 2011

- Messages

- 25

The Stainless Manifold comes with stainless Allen head bolts.

9812valveguy

New member

- Joined

- Oct 24, 2011

- Messages

- 25

One other plus with the SD manifold, the manifold for a T3 has the same size base as a T4. You could re tap and drill the T4 bolt pattern and port it out to a T4 later if you wanted to.

Also stainless holds heat better than cold rolled. And with as thick and heavy as this thing is, it would hold a lot of heat!

I happen to like the steed speed also, but like the looks Stainless Diesel manifold better.

Also stainless holds heat better than cold rolled. And with as thick and heavy as this thing is, it would hold a lot of heat!

I happen to like the steed speed also, but like the looks Stainless Diesel manifold better.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

I also don't understand why wrapping the Steed manifold with a blanket or heat wrap would void the warranty. How would adversely affect it in any way? I know they come with a Cerakote coating but they admit that it can scratch easily. Seems strange that a coating such as that could scratch so easily that you have use so much caution when installing it since the slightest bump would ruin the coating.

What if it were to be ceramic coated and then blanketed or heat wrapped?

What if it were to be ceramic coated and then blanketed or heat wrapped?

Last edited:

TMONEYDIESEL

Comp Diesel Sponsor

- Joined

- Jan 21, 2007

- Messages

- 8,706

Does this new design keep the VGT turbo in the oem location, or does it move the turbo to the center of the manifold (2nd gen style) like all his others??

MORE PICS please, different angles....THANKS!!!

TMONEYDIESEL

Comp Diesel Sponsor

- Joined

- Jan 21, 2007

- Messages

- 8,706

This is for the CR guys, turbo in stock location.

shortbusdriver

this guy

- Joined

- May 17, 2009

- Messages

- 2,318

Anyone have a pic of dual wastegate plumbing? Straight or stock

Would also like this.

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

This is for the CR guys, turbo in stock location.

I was just wondering if they had made one like this. Good timing!