Brian Lent

New member

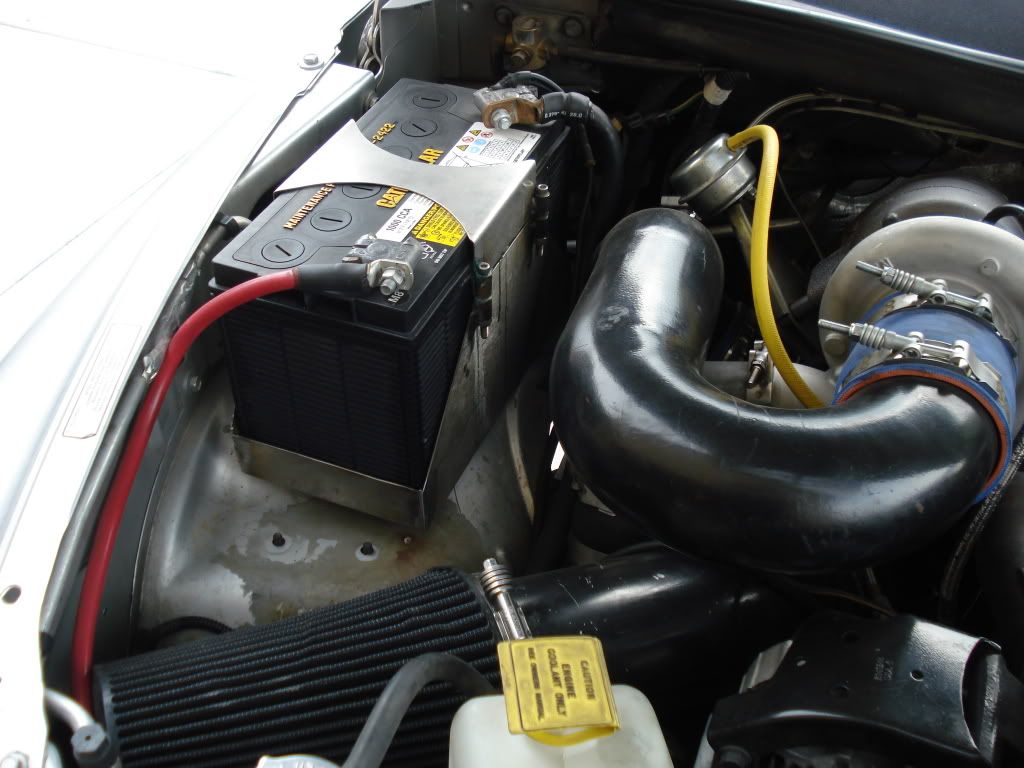

You should be proud of that truck. Alot of time and effort. I hope you are writing down what parts go where, I could just see you at an auto parts store getting parts,haha. The sales guy would hate you. Keep the pics coming, that thing is a beast.