zachu812

New member

- Joined

- Apr 20, 2016

- Messages

- 419

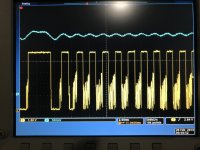

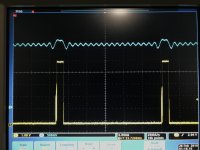

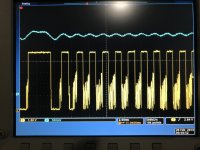

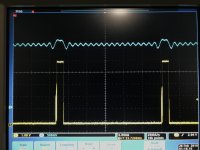

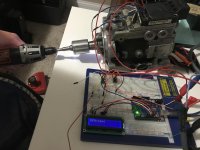

Dug into the circuit a little more today, getting closer to the signal I wanna see. In the first scope capture I’ve got the reference voltage set so that I’m getting a pulse for every tooth on the tone wheel of the VP but it’s a pretty messy signal. Adjusted it a little more for the second capture so that I’m only seeing 6 low spots in the tone wheel that will ultimately be used as the reference point to time the injection events. Not ideal but I’m thinking that’ll be enough to get things started. Gonna try to find something that’ll give me a little better signal, maybe a comparator with less hysteresis will do the trick.