tcalvin

New member

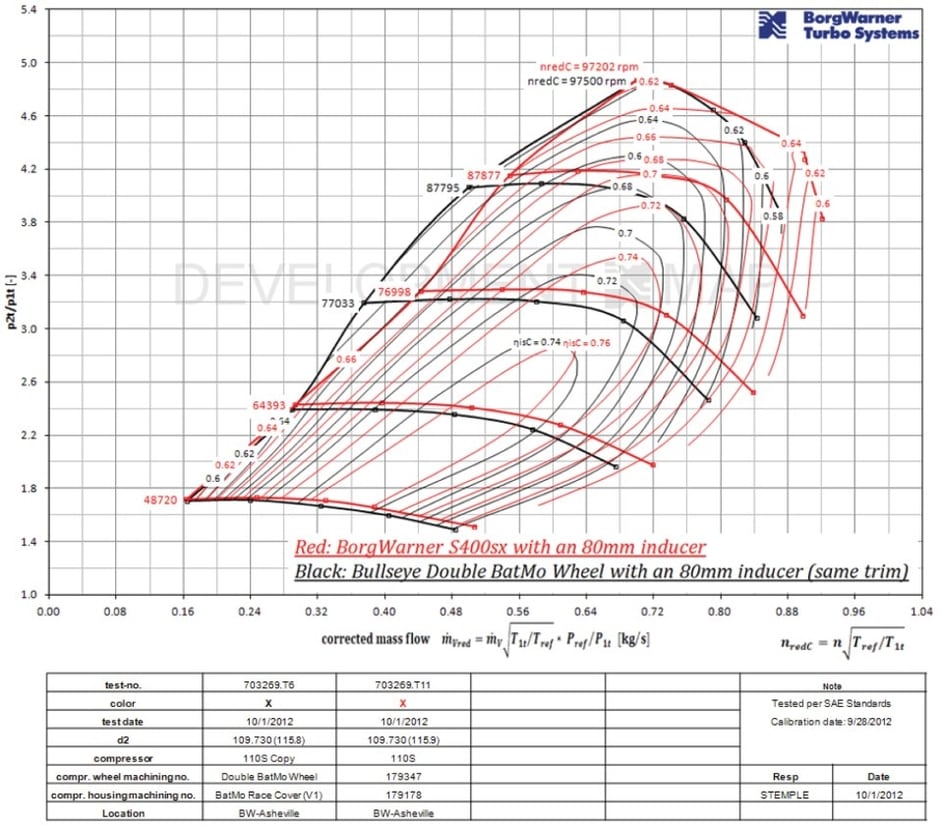

So how come no guys running BW units showed up to prove BEP wrong.

Sounds like BEP winns. At the least one of u guys running a cast BW wheel could have out performed the batmo.

From my smart car.

My engine was still in pieces being rebuilt after my 300 mile old batmo blew the f*ck up.

They replaced the charger and admitted that they had a problem with shafts in a "batch" of S300's, but I footed the bill on an engine build. I now run a cast S400.

Last edited: