You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ProStreet F-100

- Thread starter AHall

- Start date

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

Keep up the good work. What spring rate did you go with in the rear, and what did you figure the weight on the axle would be?

200 rate springs in the rear. Should be a good starting point after long conversations with Afco tech. Light by the charts , but I'm looking to have a very responsive rear. Currently have 1200# on the rear and the springs are barely working. I'd imagine I'll end up buying a couple more sets. Cheap enough for a pair.

That rake looks intimidating as hell on that old beauty. Awesome job!!

I think the oldies look awesome with some rake!!

B e a utiful!!!!!!!!!!!!!!!!!!!!!

Good luck hacking the weight off the doors. Those 'ol girls were built to be tough. Have you taken a look at the US Body Source doors???

I am getting my rear fenders from us body source. Just a touch more expensive than new steel fenders. I'm way under weight already, so if I can save a few bucks by being fatter, I'm game. No way I could compete in prostock with my budget, weight, and experience. So I'll be ballasting up to weight in the rear.

I'd be happy if prostreet minimum was dropped to 4000lbs. It has become more a purpose built class than it used to be. Making it more difficult to meet weight.

Makes my sticker peck out! You're a darn good fabricator, don't sell yourself short! If this stuff were so easy, everyone would be doing it!

Thanks!!

Last edited:

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

I think it's only there for caliper clearance anyway.

Agreed. I quite a bit of room at the moment.

She is a sexy behotch Adam, keep up the good work man. She is beautiful.

Thanks. Hope to have a real update soon. Race season is just around the corner.

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

Bought a bead roller to practice with. Metal brakes are on backorder of course. Picked up a sheet of 22ga and 18ga to practice with. Sheet metal work is all new to me. I built a temporary guide to help with straight lines. Luckily I can always put carpet down if the floor turns out less than desirable.

6 speed 90

Drunken hillbilly

- Joined

- Oct 20, 2014

- Messages

- 1,195

Holy chit man! I love it!!!

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

Working on the shifter mounting setup. I have to admit it is fun sitting in the driver's seat with one hand on the steering wheel and the other on the shifter.

Built an engine stand for when I pull the engine to build the pan and finalized all the misc things.

I'd really like to do drag week someday. I may keep the stock door panels with cut outs for speakers so I have some tunes. Also I found another stepside ford f100 without a cab. I may buy it to convert into a matching trailer to pull the racing gear around.

Built an engine stand for when I pull the engine to build the pan and finalized all the misc things.

I'd really like to do drag week someday. I may keep the stock door panels with cut outs for speakers so I have some tunes. Also I found another stepside ford f100 without a cab. I may buy it to convert into a matching trailer to pull the racing gear around.

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

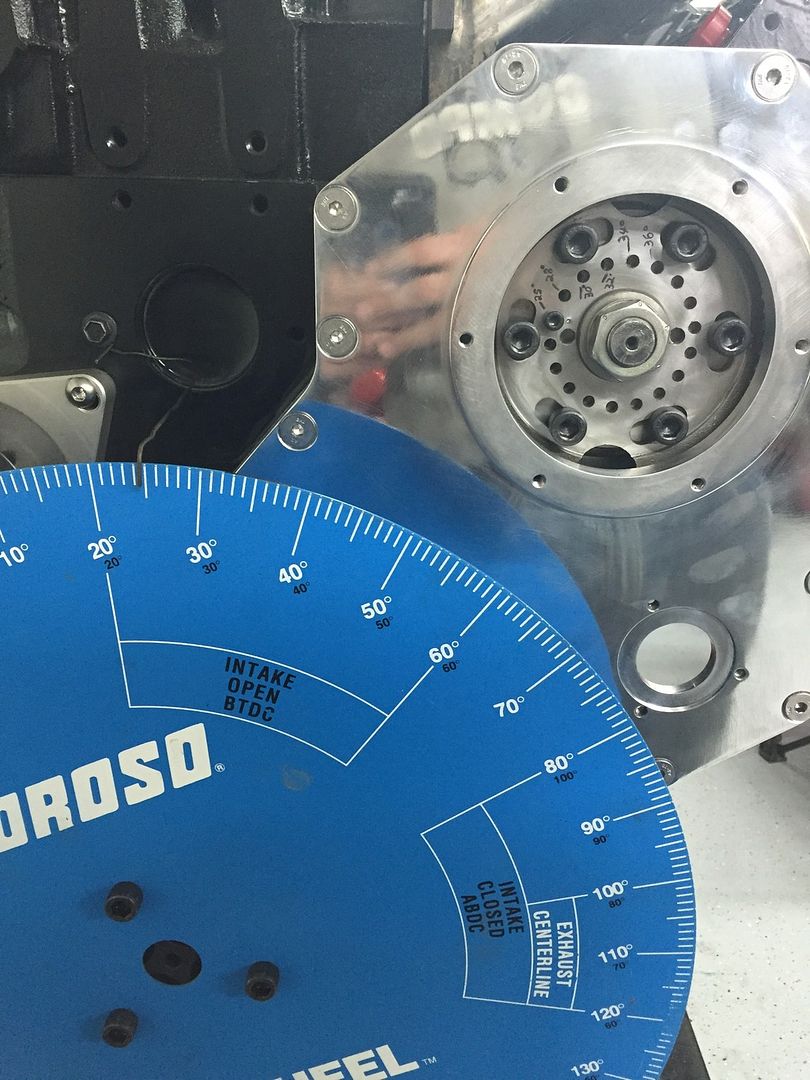

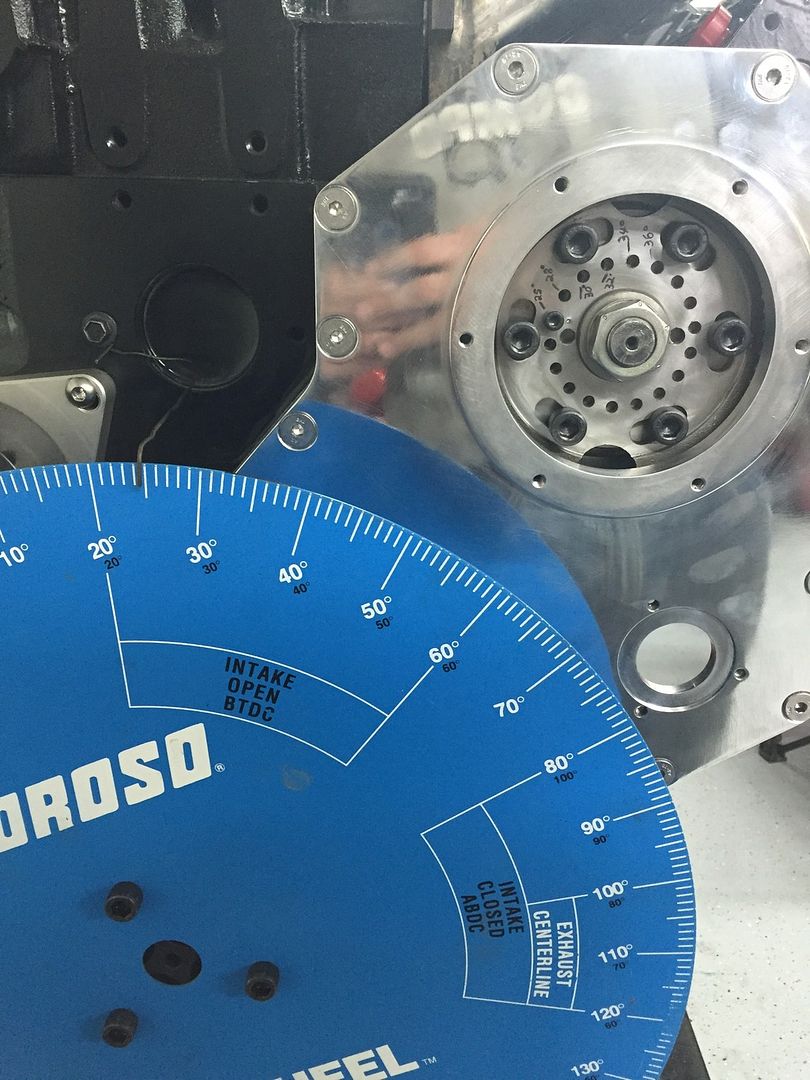

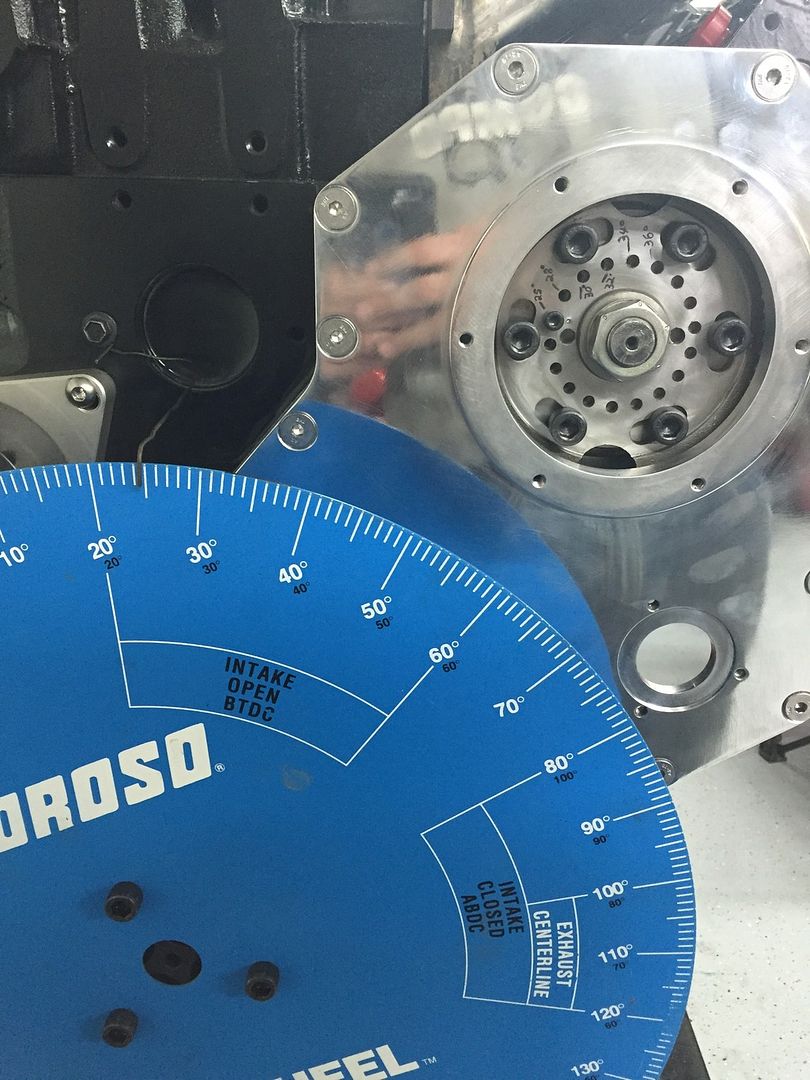

I did some polishing on the aluminum engine pieces while they were off. Been so long I wanted to check to make sure a few things were sealed and buttoned up correctly. Degree'd my cam in and documented where everything was. Set the timing and marked future settings for quick changes. I look forward to timing changes in just a few minutes.

Nearly finished with the oil pan now.

Pulled the truck outside for the first time in many months. Sfi chassis cert inspection is in a couple weeks. Just about ready now and have an appointment scheduled.

Testing some high pressure water injection at 1100psi and welded bungs in the intake manifold for direct port.

Nearly finished with the oil pan now.

Pulled the truck outside for the first time in many months. Sfi chassis cert inspection is in a couple weeks. Just about ready now and have an appointment scheduled.

Testing some high pressure water injection at 1100psi and welded bungs in the intake manifold for direct port.

WUnderwood

Moderator

- Joined

- Aug 10, 2006

- Messages

- 8,418

Keep up the good work, it'll pay off in the long run!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

AHall

Hobbyist

- Joined

- Apr 2, 2007

- Messages

- 4,603

Thanks, Will.

Here's a short clip messing with different nozzles. This is (3) 225ml snow nozzles at 825psi. Actual measured flow was 800ml/min per nozzle.

[ame="http://http://www.youtube.com/watch?v=X-tHN1TAxjk"]http://http://www.youtube.com/watch?v=X-tHN1TAxjk[/ame]

Picked up some valves to help control the fuel and boost from the driver's seat.

Here's a short clip messing with different nozzles. This is (3) 225ml snow nozzles at 825psi. Actual measured flow was 800ml/min per nozzle.

[ame="http://http://www.youtube.com/watch?v=X-tHN1TAxjk"]http://http://www.youtube.com/watch?v=X-tHN1TAxjk[/ame]

Picked up some valves to help control the fuel and boost from the driver's seat.

I did some polishing on the aluminum engine pieces while they were off. Been so long I wanted to check to make sure a few things were sealed and buttoned up correctly. Degree'd my cam in and documented where everything was. Set the timing and marked future settings for quick changes. I look forward to timing changes in just a few minutes.

Nearly finished with the oil pan now.

Pulled the truck outside for the first time in many months. Sfi chassis cert inspection is in a couple weeks. Just about ready now and have an appointment scheduled.

Testing some high pressure water injection at 1100psi and welded bungs in the intake manifold for direct port.

That looks straight bad a$$, good work.