NickTF

Single turbo turd.

- Joined

- Jun 4, 2007

- Messages

- 5,887

....looks like when I thought I had a blown gasket and started seeing coolant in the resevoire the gasket had been hurt just a little bit. Been riding like that for a while but the way it busted no coolant into oil or coolant into the pistons. The front is what went and lucky again it just went from the coolant passage to the front of the motor.

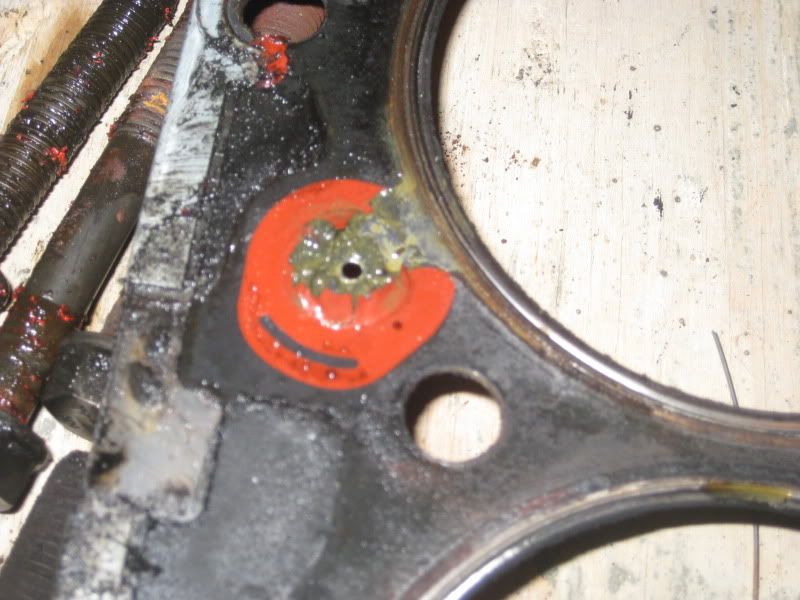

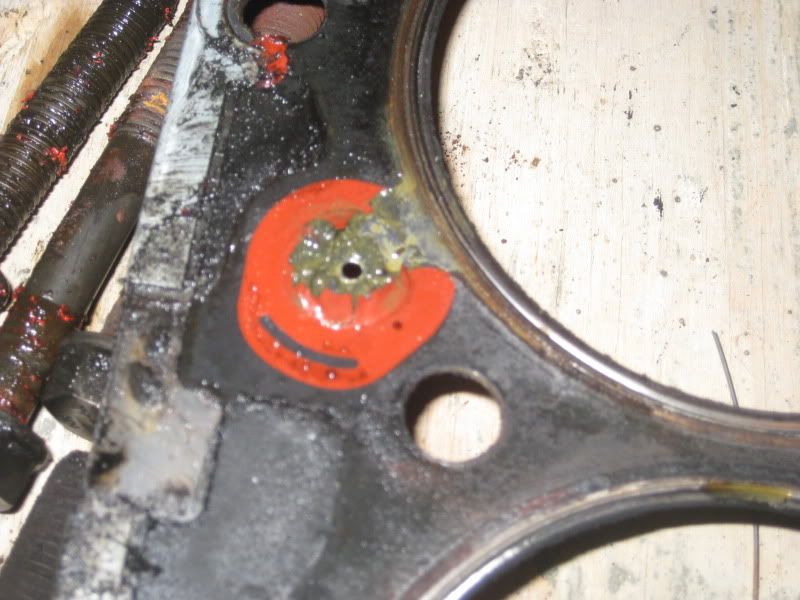

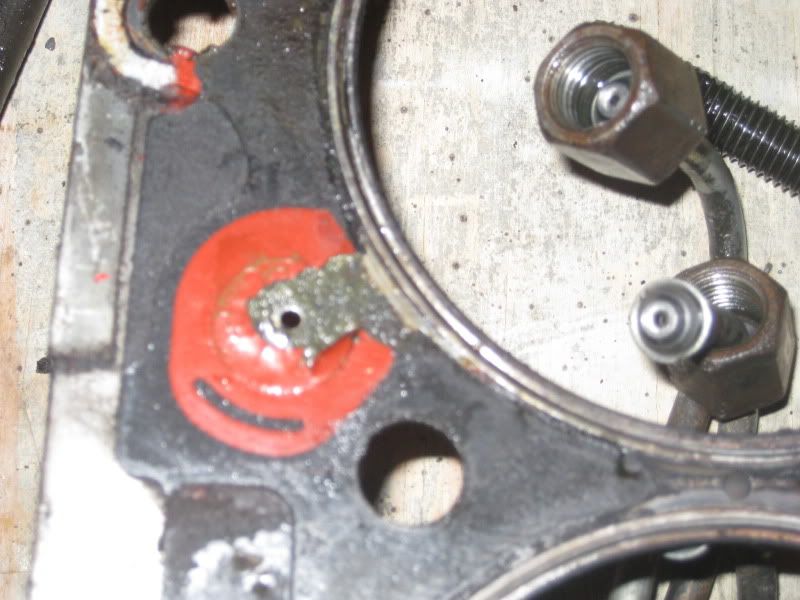

Here's the damage I caused months ago when I thought I had a hg issue. Wasn't severe enough to cause a failure though but does explain why the pressure showed in the coolant system

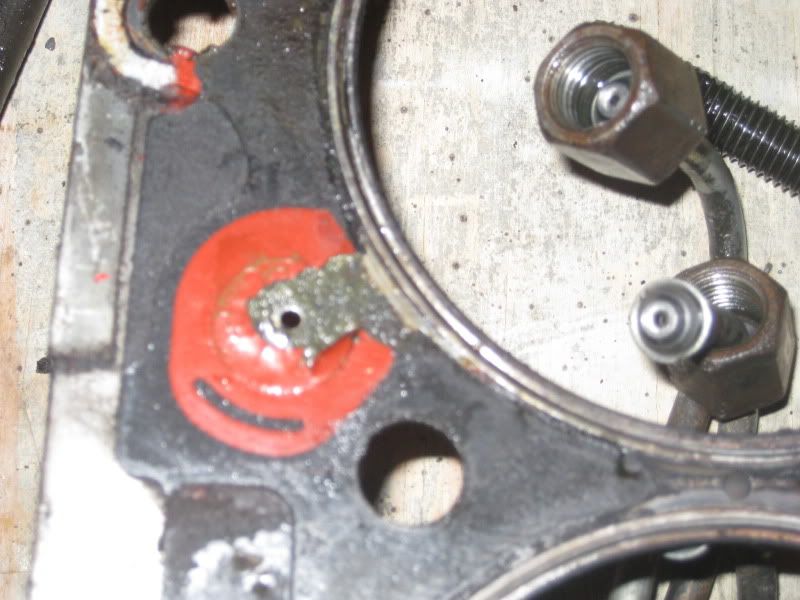

Hard to see in this photo but the gray material between the fire ring and the front of the gasket is what went causing coolant to run right out of the front of the motor.

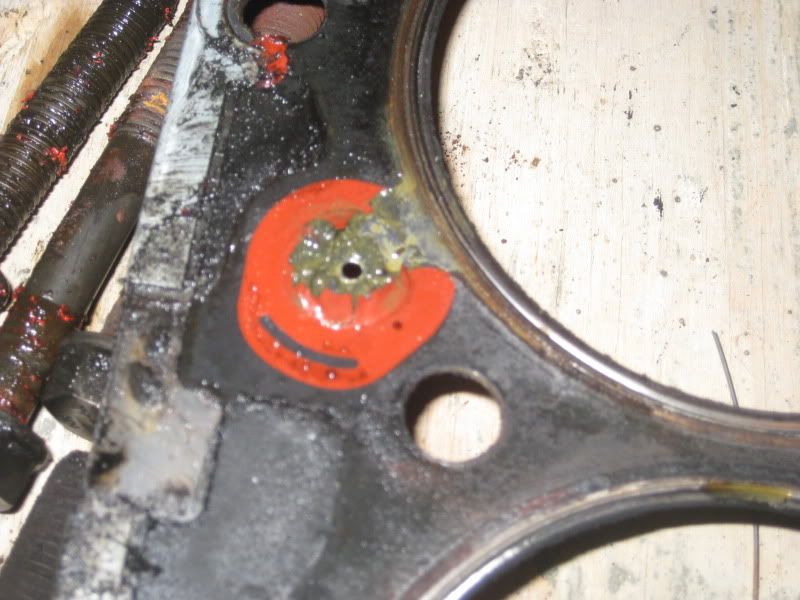

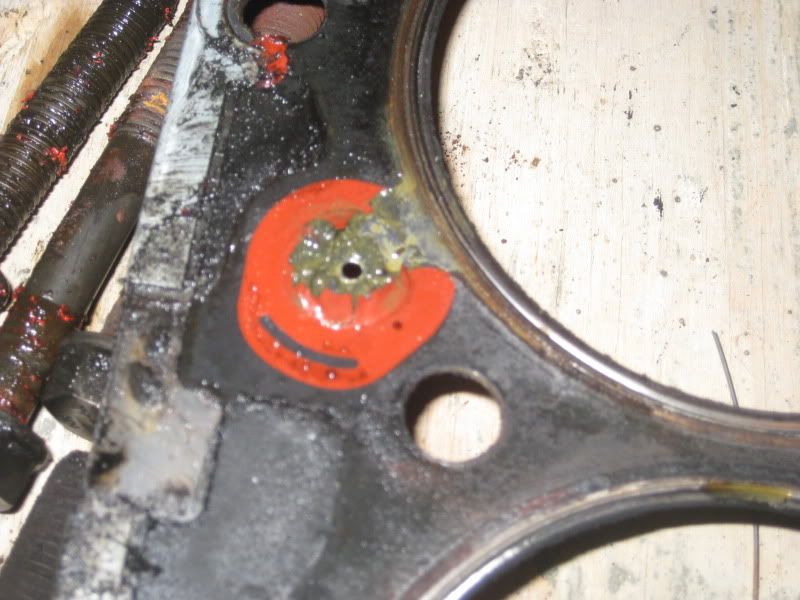

The other area that was contributing to the system being pressurized from time to time.

Man that's one good lookin motor for the abuse it's put up with. around 126,000 miles

The solution! A1 studs. Bottom tapped all holes and ready to put them in tomorrow.

Hilarious you have to pull the head with a fricken crane ha!

The hole shebang!

Here's the damage I caused months ago when I thought I had a hg issue. Wasn't severe enough to cause a failure though but does explain why the pressure showed in the coolant system

Hard to see in this photo but the gray material between the fire ring and the front of the gasket is what went causing coolant to run right out of the front of the motor.

The other area that was contributing to the system being pressurized from time to time.

Man that's one good lookin motor for the abuse it's put up with. around 126,000 miles

The solution! A1 studs. Bottom tapped all holes and ready to put them in tomorrow.

Hilarious you have to pull the head with a fricken crane ha!

The hole shebang!