Diesel Tech

#1 Crusty Old Fart

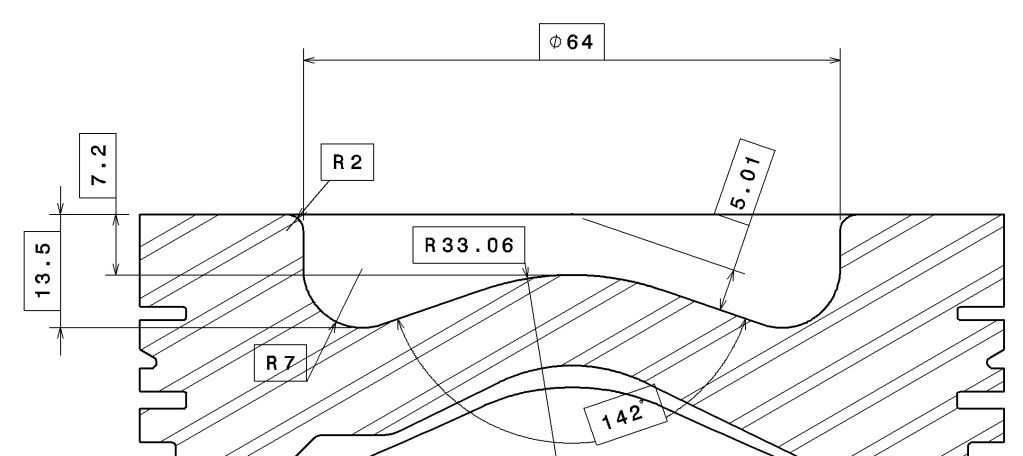

You can calculate bowl and wall contact based on straight line numbers but your missing that each hole sprays as a cone and the fuel is breaking up into a gas as it travels. Then you add in the air turbulence and pressure differences caused by the bowl design and compression, things are going to change more than a little. Now add in the changing rail pressure and it all changes again. The only true test is to run it and then see what it looks like unless you have big bucks and can drill the cylinder for a high speed camera to watch it in slow mo.