Smokem

Turbler

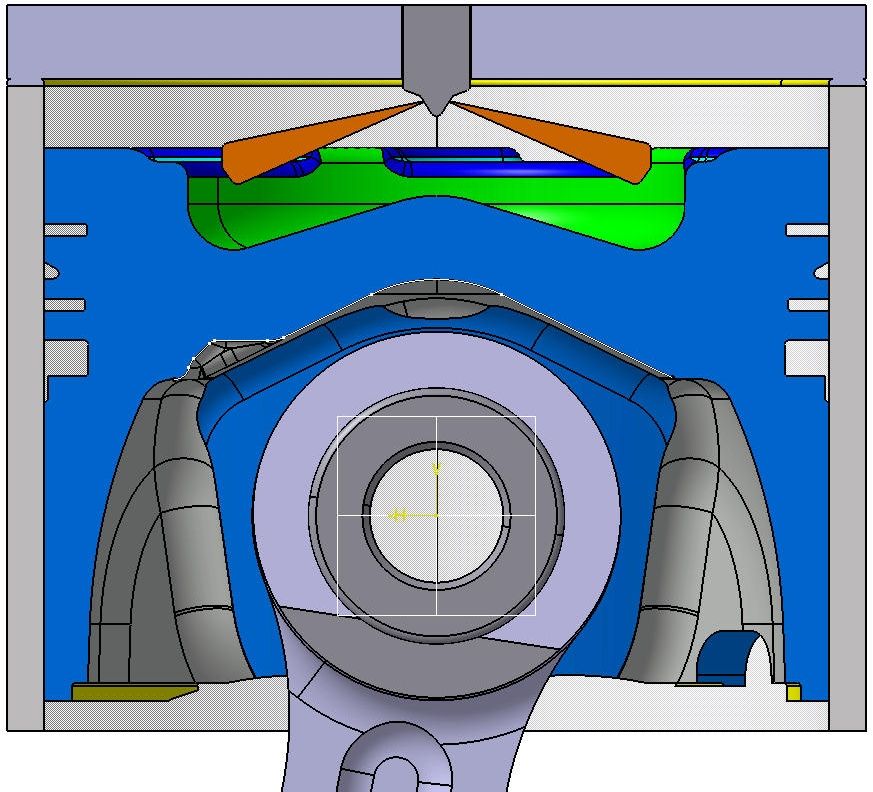

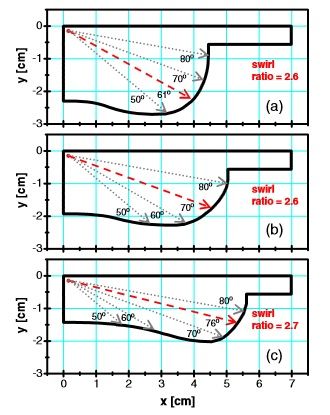

I see two differently designed pistons, that would take different nozzles.

Yet the Cummins piston design is very very similar to many pistons used with wide cone angle nozzles in multiple applications, I think this is the part you are missing.