BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

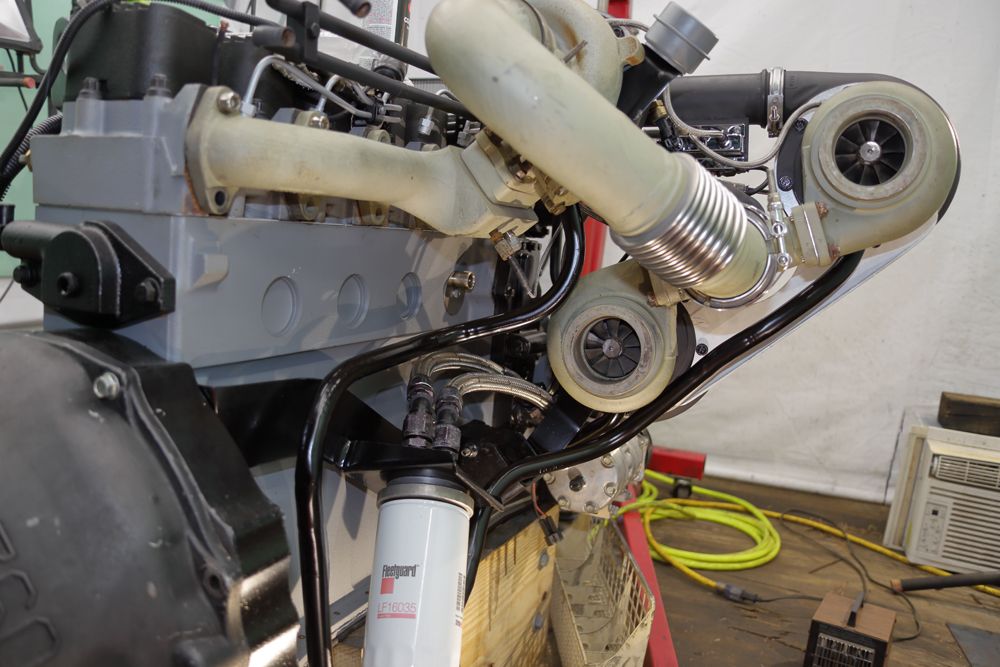

Interesting. I don't recall seeing this article in any of the boxes when I got the turbos. I may be mistaken but, . .Borg Warner is rather clear on their recommendations, I am unsure why this information isn't more common.

I'm disappointed my dumbazz didn't catch this to start with. :bang