Ghostman

24v crazy

- Joined

- Aug 24, 2012

- Messages

- 2,819

Our current head is over 300cfm a port, and other then the expense would be at home on a dd.

Wow! That is pretty extensive!

Our current head is over 300cfm a port, and other then the expense would be at home on a dd.

If the plenum under the SC was one piece and the runners were one piece instead of 8 I don't think you'd see much difference.

Anyone give any thought as to how much of a radii can be employed nominally for our air charge entering the runner? I have heard around a 1/2" is stable.

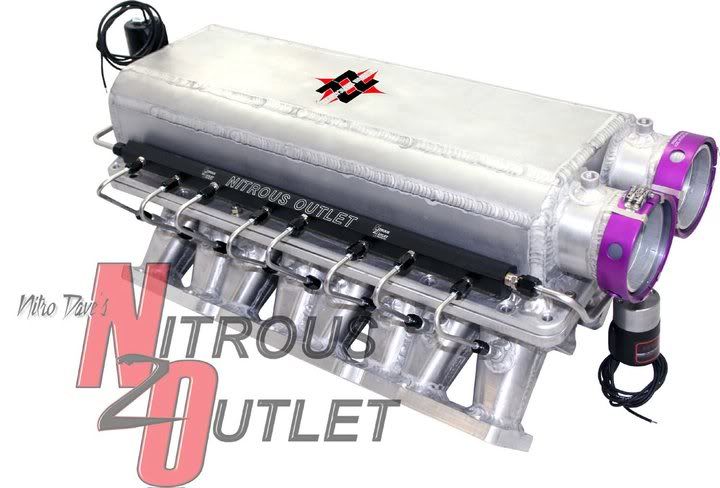

u mean something like this?

Yes in the general sense. Lookin' sharpe on the base of that intake Dmaxsandwich! What are some more thoughts of yours on this topic?

I was thinking about the runners ends that protrude slightly into the plenum manifold though, sort of like a donut at the end with an equal & opposite radii meeting the intake floor to keep a transition smooth from the plenum floor as well.

Granted we have positive & negative pressure waves and rarefaction waves etc to deal with Greg you are touching on a subject that is of great importance. Friction from flow however I believe is very minimal when trying to reduce it further with different textures. Albeit it can be the decider between opponents. The shape of the plenum I have read plays a role in canceling out certain waves that may interfere with wave tuning at the desired rpm for peak power? Right?

I am not sure but wouldn't runner shape have a hand in this as well guys? I am just asking that since parameters are crucial in optimum cylinder fill.

op:

...changed the intake, intercooler, and some little things and made +180hp/280 ftlb over last years numbers. i really think its about finding your motors limiting factor to gaining hp.... the guys that only gain 3-4hp from a different intake i would say that their intake design wasnt their limiting factor, but thats just my 2 cents

Our current head is over 300cfm a port, and other then the expense would be at home on a dd.

how much you charge me for a head, bare, ported to flow this kind of air? i will buy one right now. call or pm me. 812 229 1290.

Anyone have thoughts to wether the wave itself changes between a N/A system to a forced induction system.......