You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Intake: side vs top entrance

- Thread starter jlibert

- Start date

Highwayman

bored.

- Joined

- Oct 12, 2014

- Messages

- 2,087

*disclaimer* I'm not smart.

For some reason, I'm thinking of a tubular intake with a cone inside that helps to balance flow/velocity throughout the cylinders would work well.

Is this how most runner intakes are, or is it just a hollow tube?

For some reason, I'm thinking of a tubular intake with a cone inside that helps to balance flow/velocity throughout the cylinders would work well.

Is this how most runner intakes are, or is it just a hollow tube?

djforrest119

New member

- Joined

- Oct 13, 2014

- Messages

- 21

I'm a big believer in dual plenum (Lehmann) manifolds offer the best air distribution.

I remember Lavon or Drew talking last year that the top entrance worked better vs a front entrance on a runner style intake using the analogy of a water hose shooting straight down a pipe and the stream not spreading out until it hit the end compared to the water hitting a flat surface and spraying perpendicular to the original direction of flow (ie. towards the intake runners in the head). Yet, nearly all the pulling guys use a front entrance style and they know a thing or two about making power.

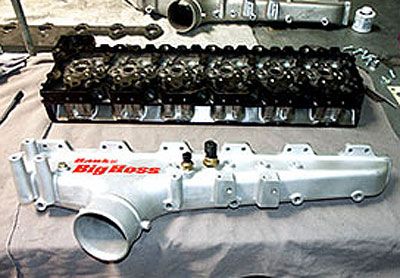

Fleece seems to swear by the Banks intake on their Comp6.4 builds.

That's all I got. Never seen any flow number comparisons, just thinking out loud.

I remember Lavon or Drew talking last year that the top entrance worked better vs a front entrance on a runner style intake using the analogy of a water hose shooting straight down a pipe and the stream not spreading out until it hit the end compared to the water hitting a flat surface and spraying perpendicular to the original direction of flow (ie. towards the intake runners in the head). Yet, nearly all the pulling guys use a front entrance style and they know a thing or two about making power.

Fleece seems to swear by the Banks intake on their Comp6.4 builds.

That's all I got. Never seen any flow number comparisons, just thinking out loud.

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 11,989

I don't remember the formula now, but I believe all the big plenums the pullers run are build to hold a certain amount of air. Like 1.5x the volume of the engine, or something along those lines....between that, and the shape of the runners is why they use them on the high power pullers.

Definitely not a fact, but it's something I remember reading way back when, and my head porter and I also talked about it some back when I had a 12v head done many moons ago.

As for the OP...I don't know that you'll notice a huge difference either way, the main goal is more access to port the head, as far as I know.

Chris

Definitely not a fact, but it's something I remember reading way back when, and my head porter and I also talked about it some back when I had a 12v head done many moons ago.

As for the OP...I don't know that you'll notice a huge difference either way, the main goal is more access to port the head, as far as I know.

Chris

takedown95

New member

- Joined

- Aug 18, 2011

- Messages

- 2,841

I'm a big believer in dual plenum (Lehmann) manifolds offer the best air distribution.

I remember Lavon or Drew talking last year that the top entrance worked better vs a front entrance on a runner style intake using the analogy of a water hose shooting straight down a pipe and the stream not spreading out until it hit the end compared to the water hitting a flat surface and spraying perpendicular to the original direction of flow (ie. towards the intake runners in the head). Yet, nearly all the pulling guys use a front entrance style and they know a thing or two about making power.

Fleece seems to swear by the Banks intake on their Comp6.4 builds.

That's all I got. Never seen any flow number comparisons, just thinking out loud.

Once it's pressurized this no longer applies. Its the same as a common rail set up. The entire tube is pressurized and the air only flows to where the opening is.

The only difference I noticed on a top, versus a side, versus a front runner is on the top and the side the cylinders directly in front of the opening ran a little hotter and a little leaner. Once I switched to a front individual runner they balanced out.

I don't have HP comparisons because I also changed cams and other tuning. I do have the log on the cylinder temps though.

djforrest119

New member

- Joined

- Oct 13, 2014

- Messages

- 21

Once it's pressurized this no longer applies. Its the same as a common rail set up. The entire tube is pressurized and the air only flows to where the opening is.

Yea, that seems painfully obvious now. Growing up around NA motors gets me off track now and then when it comes to airflow haha

The formulas that go into sizing some of the parts has always been really interesting to me. There's an old timer I work with telling that was me about how they calculated the dual plenum manifolds for turbo Datsun engines back in the day. The guy had countless hours on a flowbench and ported heads for all the top sprint cars and Baja racers in California (so he says) but couldn't put down the bottle and definitely isn't as sharp as he used to be so a lot of what he says (especially after a couple beers) goes in one ear and out the other.

chris lang

New member

- Joined

- Jun 27, 2010

- Messages

- 843

I've always thought side flow were better for low boost flow because it has less bends, and top or runners were better for something that's built to perform under constant pressure not worrying about on and off the accl pedal drivability.

jlbayes

New member

- Joined

- Mar 15, 2011

- Messages

- 2,399

Once it's pressurized this no longer applies. Its the same as a common rail set up. The entire tube is pressurized and the air only flows to where the opening is.

The only difference I noticed on a top, versus a side, versus a front runner is on the top and the side the cylinders directly in front of the opening ran a little hotter and a little leaner. Once I switched to a front individual runner they balanced out.

I don't have HP comparisons because I also changed cams and other tuning. I do have the log on the cylinder temps though.

I know of some air flow threads and intake discussions on another forum that would very much disagree with that first statement. Your second statement also contradicts it.

takedown95

New member

- Joined

- Aug 18, 2011

- Messages

- 2,841

I know of some air flow threads and intake discussions on another forum that would very much disagree with that first statement. Your second statement also contradicts it.

They are free to disagree all they want.

My second statement is complimentary to my first statement which is based on a pressurized tube. Not a side draft or top entrance intake as these are not tubes.

I used a common rail fuel set up as the example of a individual runner intake with a front entrance.

takedown95

New member

- Joined

- Aug 18, 2011

- Messages

- 2,841

It is still a pressurized vessel no matter how you try to twist it.....

I'm not trying to twist it. I am just clarifying my position.

WUnderwood

Moderator

- Joined

- Aug 10, 2006

- Messages

- 8,418

I don't have as much experience or knowledge as most guys, but I've always thought that the side entrance was/is better than the top. I've read somewhere that air doesn't like to make more than a 15* turn...

kjpcummins

New member

- Joined

- Feb 15, 2009

- Messages

- 2,322

If your two choices are top and side I would go with top. When the air flows into the plenum and makes a 90deg turn it is redistributed more evenly than if it came in from the side straight at the intake runner. Given that your plenum is correctly sized for rpm range and cubic inch. At the same time in most setups top adds another bend in the piping compared to side entrance. This would most likely negate anything gained by top feed. My personal choice would always feed from front or rear in high performance application not in the middle of the runners.

CorneliusRox

Seasoned Rookie

- Joined

- Dec 13, 2012

- Messages

- 4,154

It is still a pressurized vessel no matter how you try to twist it.....

You're assuming a constant pressure always. That's not the case.

If you've got a front mount, the velocity of the air is going to take it towards the rear of the engine/head which will leave lowest pressure at the first cylinder.

I'm not saying I know which one is better/best, I'm just saying that it's not a constant pressure vessel. It's a variable system. I don't think there's a one size fits all when you're trying to get down to this level of tuning.

Then there's the whole rabbit hole of intake runners and injector pulsing (calculated at the speed of sound per temp/pressure/rpm).

I'm a big believer in dual plenum (Lehmann) manifolds offer the best air distribution.

x2

jlbayes

New member

- Joined

- Mar 15, 2011

- Messages

- 2,399

You're assuming a constant pressure always. That's not the case.

If you've got a front mount, the velocity of the air is going to take it towards the rear of the engine/head which will leave lowest pressure at the first cylinder.

I'm not saying I know which one is better/best, I'm just saying that it's not a constant pressure vessel. It's a variable system. I don't think there's a one size fits all when you're trying to get down to this level of tuning.

Then there's the whole rabbit hole of intake runners and injector pulsing (calculated at the speed of sound per temp/pressure/rpm).

There is a reason you do not generally see straight tube intakes in pressurized intakes for gassers. The air will run right past the port and not make the turn. Look at the holley hi ram for ls engines or Hogans bottom entrance manifolds. They try to slow the air down, not force it into the ports. All this stuff has been done for years on gas engines. For some reason this industry is slow to follow. I am a fan of the Lehmanns. Like to see someone actually spend some time with them.

kjpcummins

New member

- Joined

- Feb 15, 2009

- Messages

- 2,322

The reason many don't mess with a lehman intake is the cost/time into a perfectly tuned manifold isn't worth 10hp. Especially when a change to the engine like cubic inch or a cam change can cause you to start all over again.

EnduringAtlas

New member

- Joined

- Oct 21, 2015

- Messages

- 86

Some good reading in the link below although it may not directly apply to the diesel world. A lot of the issues it seems with boosted gas engines is the redirected air do to the throttle body plates. But still may have something of value.

Intake manifold design | Page 11 | The Turbo Forums

Intake manifold design | Page 11 | The Turbo Forums