JQmile

Comp Diesel Sponsor

- Joined

- Nov 19, 2006

- Messages

- 6,976

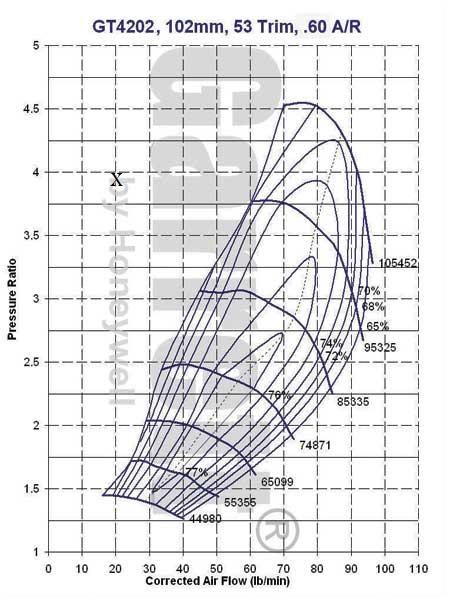

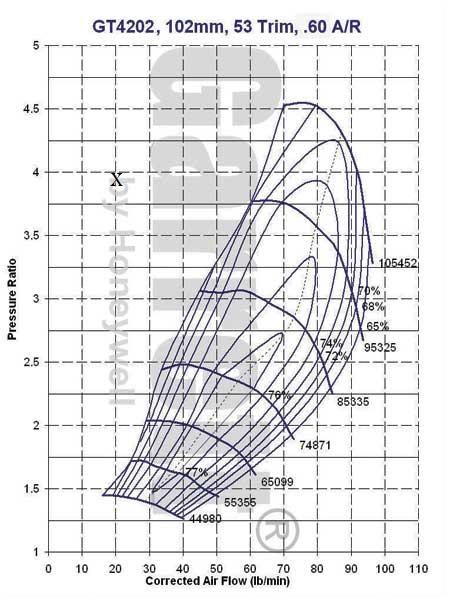

OK let's say your power peak is at 5,000 rpm (which would take a lot of doing) that means with the Cummins crappy head you would need about 500 cfm at 80% VE, so let's say you get it up to 90%, and you're at 600cfm. Divided by 2 and that means you need about 300 cfm or 21 lb/min of air per turbo. At a 4:1 pressure ratio, (45 -ish psi which isn't much for a diesel) here's where you are on a compressor map of a 74mm (inducer, not exducer, right?) Garrett turbo. Waaaaay off the map, and way into surge. Even if you did get this to work, it's clearly not an efficient turbo setup for the engine. just my $.02 I'll butt out now.