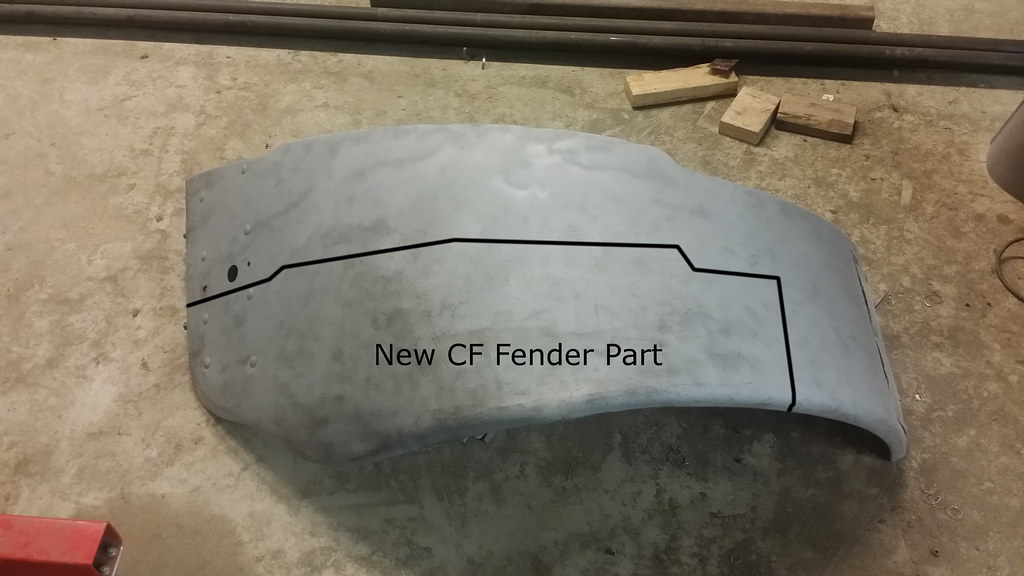

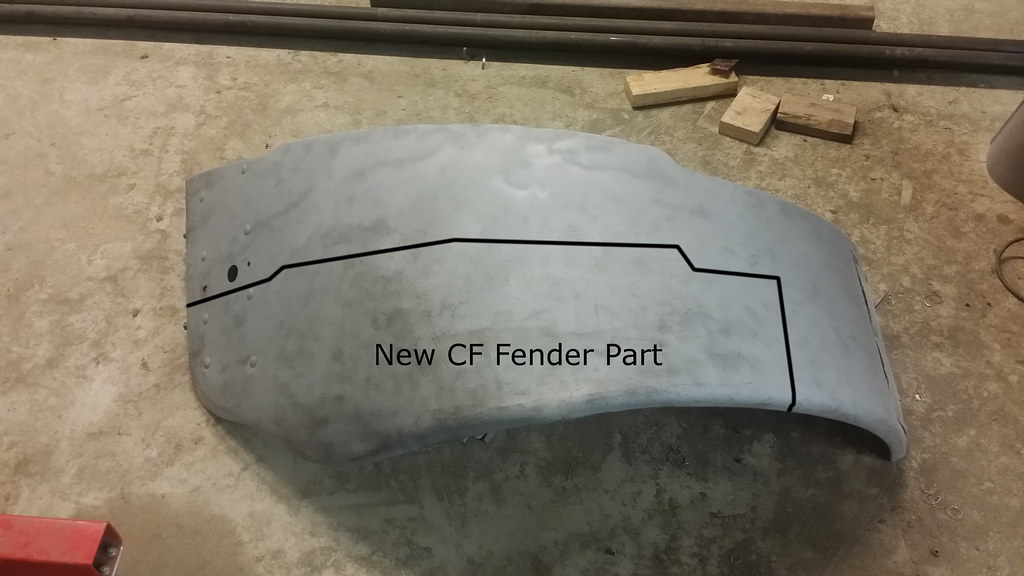

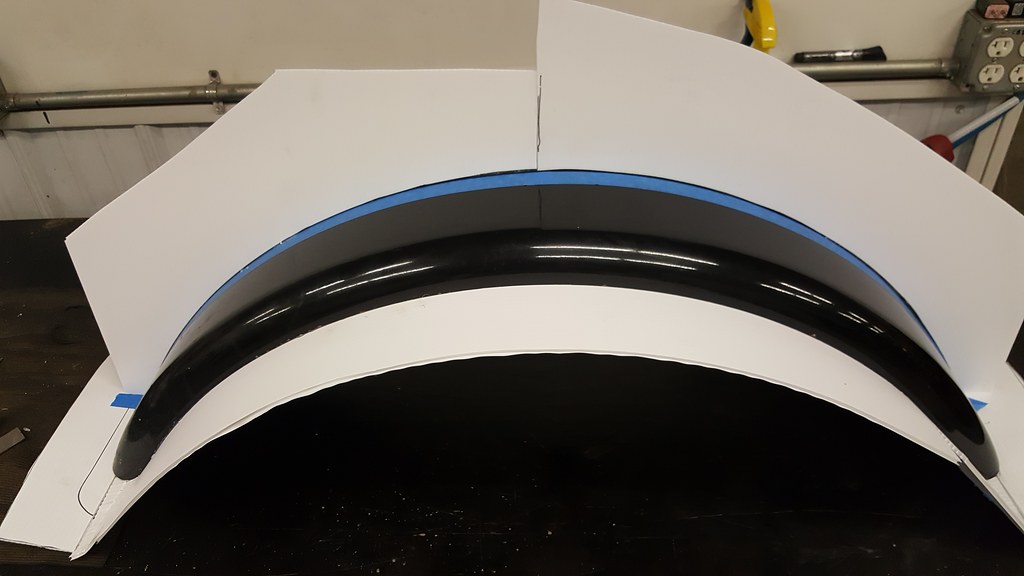

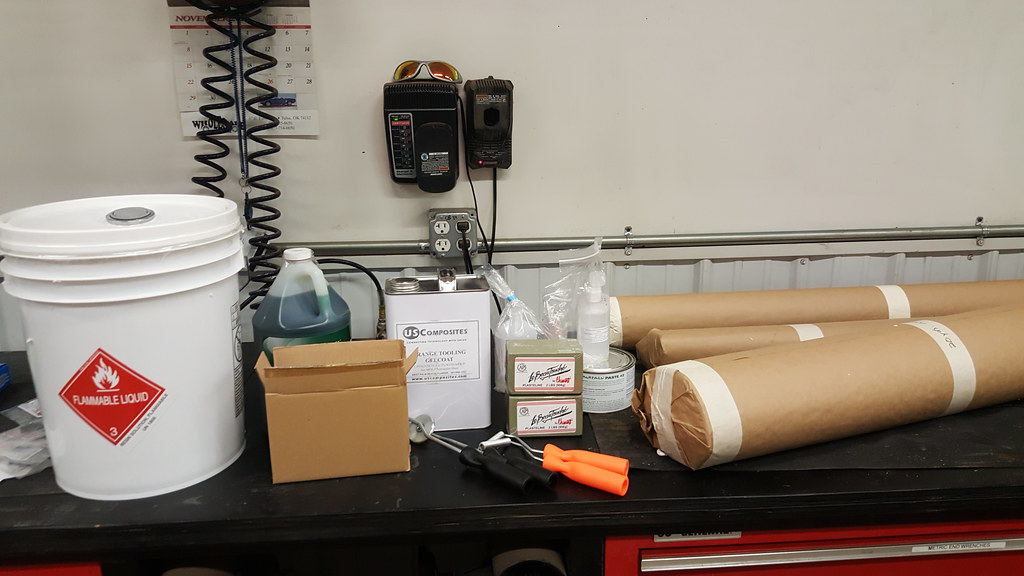

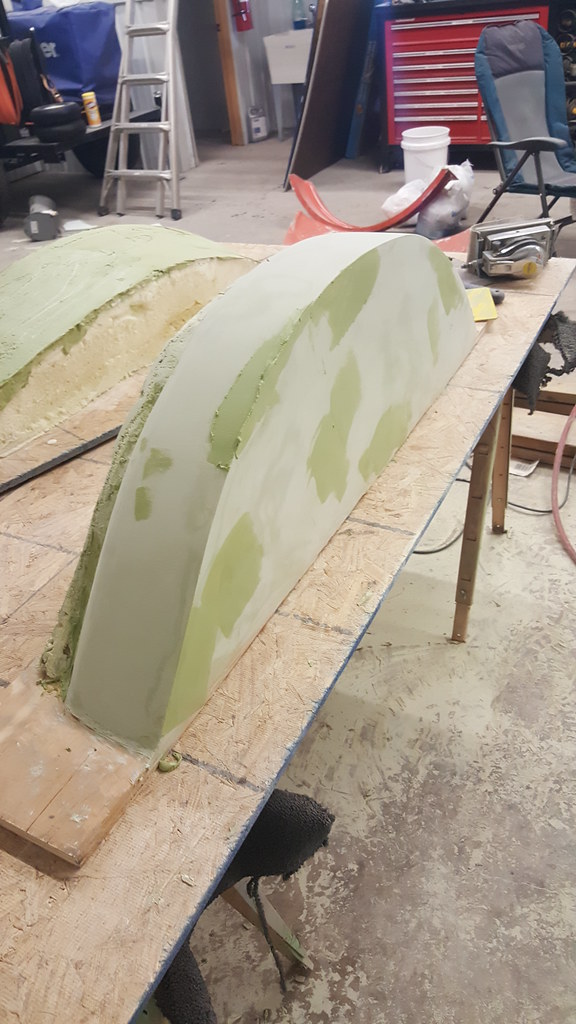

Been working on the fender molds and researching and ordering some parts for the truck. Found that the filler I'm using does eat into the polyurethane foam a bit, as the rear fender has about 4 areas where the filler sunk in. Been working those areas out and filling and rough smoothing with air power sanders to get it all level and a consistent profile. Hoping to have it where I can start with detailed filling and sanding in the next day or two.

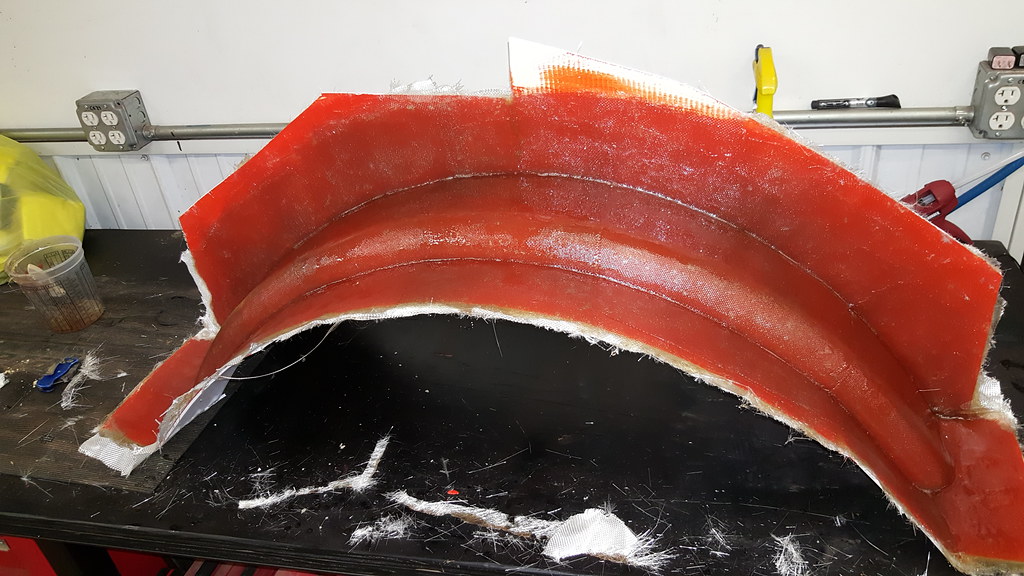

I tried something different on the front fender I've made a foam mold of, I covered it in a couple of layers of plaster of paris before starting on the filler. I applied the first coat of filler to it last night before I had to run and take the wife to go see Trans Siberian Orchestra. Hopefully it works out with the plaster of paris separating the foam and filler. Waiting to make the other front fender till this test plays out.

On other fronts, ordered new weld in tube adapters for the longer front control arms, already have the dom tubing here at the shop that's left over from my track bars that I built last year. Looking at moving the front coil spring buckets 16" forward on the frame, and will have to move to full hydraulic steering so I'm trying to decide on the route to go with either buying a complete setup or piecing one together.

Planning on ordering new front springs from Dodge Offroad, a pair of their progressing 3" coils, waiting to hear back from them on which would be the right ones for the weight on the front of my truck, since it's not a standard application.

The front Bilstein 5160's are going to be sent to bilstein and get revalved to a 90/10 setup.

The p pump is getting turned into a 13mm pump and maxed out and balanced and will probably order a 1.10 ar housing for the s475.

Ordered a spool gun for my tweco 211i and got it in yesterday, need to pick up a bottle of argon and then I can start playing with aluminum mig welding to build the frame for the front one piece clip and possibly new mounts for all the bed components.

Also planning on changing gears from the 5.13's I'm running now to 6.17's to see if I can get the transmission to live. After talking with a few people I trust, we think that's the root cause, I jumped to too high of a ratio. Most gas fast trucks try to be around 9 to 1 overall diff + transfercase low range, my old setup with 3.55's and the np205 put me at 7:1 overall and the trans was living then.