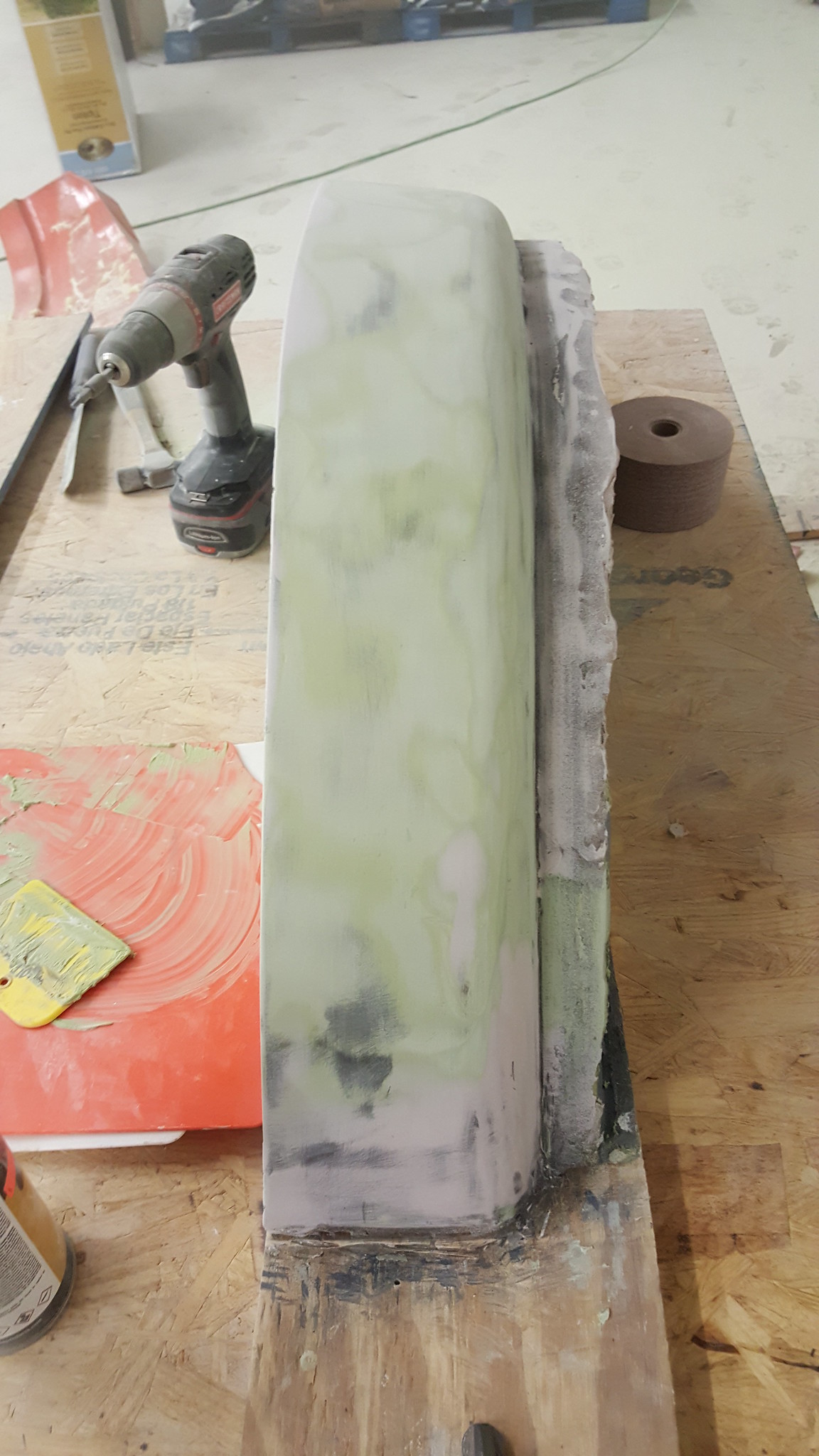

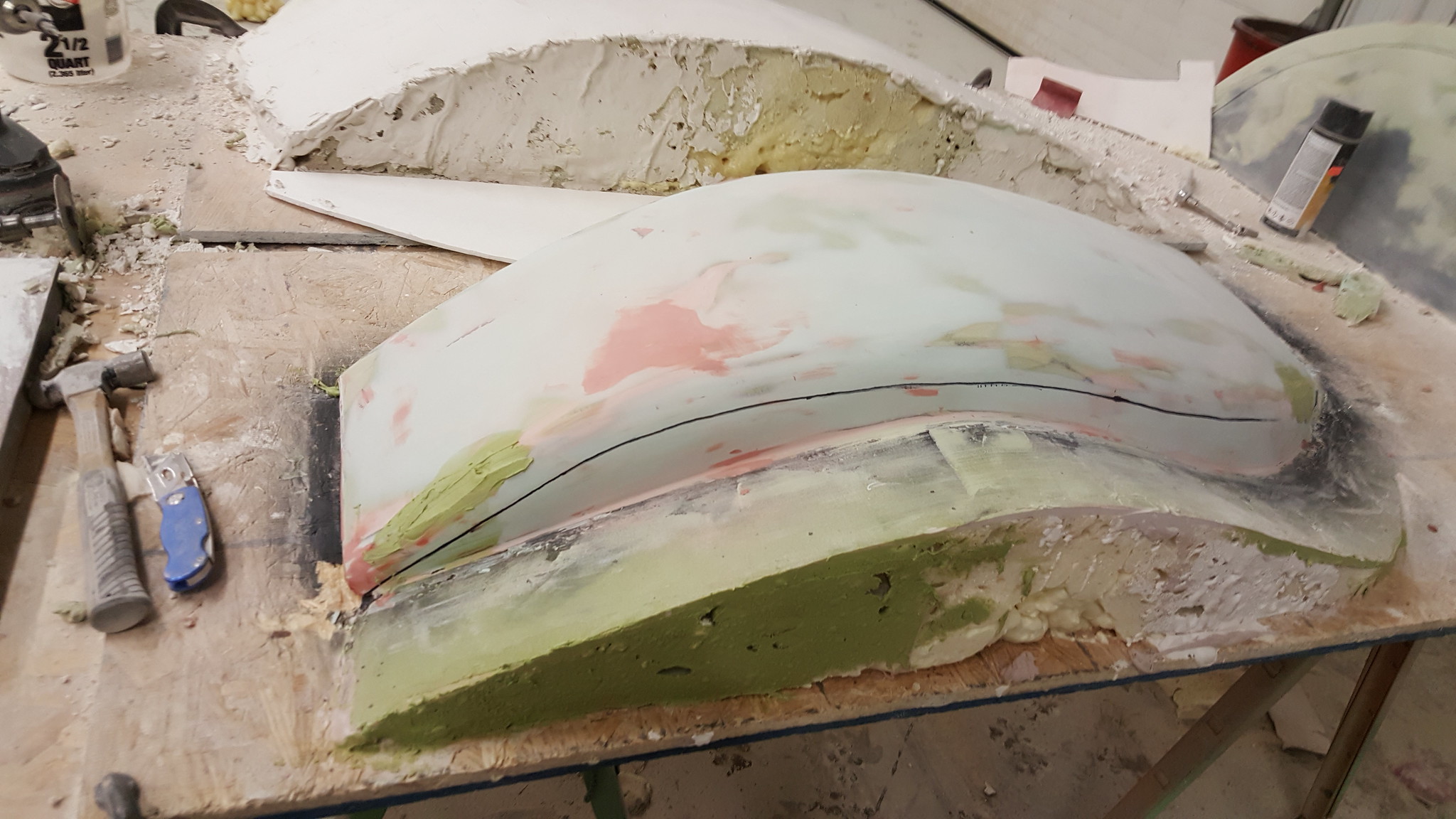

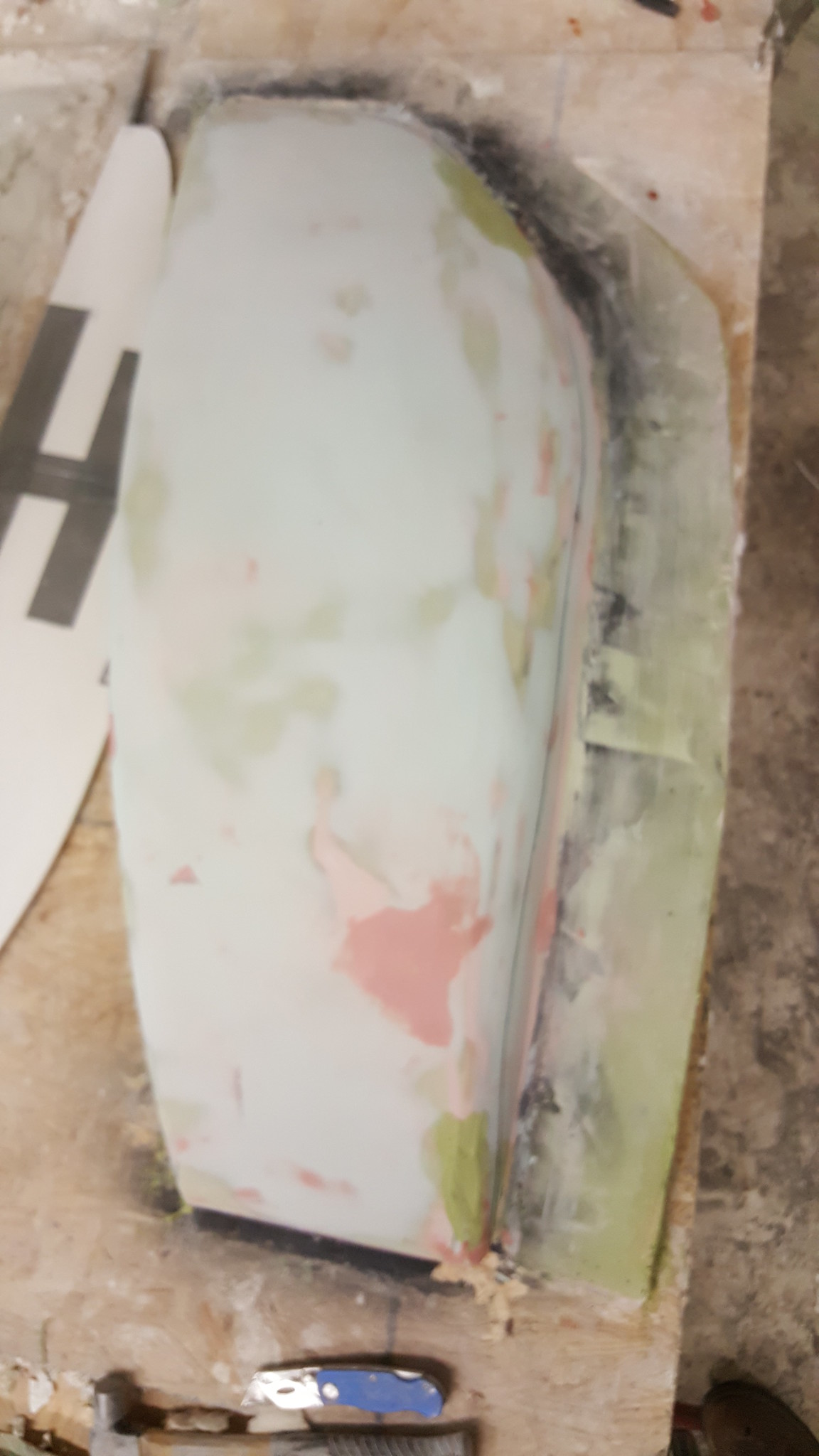

The first coat of primer looked good, there were a couple of places I had to fix so I put a little spot putty on them and it somehow caused that primer to turn loose where I applied it. So bigger sanding job, finish putty used and then sanded that down on the few spots. Shot another coat of primer, this time a primer / sealer. Well it turned to caca real fast. Weird cracks, tried sanding it down and it apparently affected the first coat of primer, you could take a scraper and just scrape both layers off in spots. So I scraped off what I could and then sanded it further down.

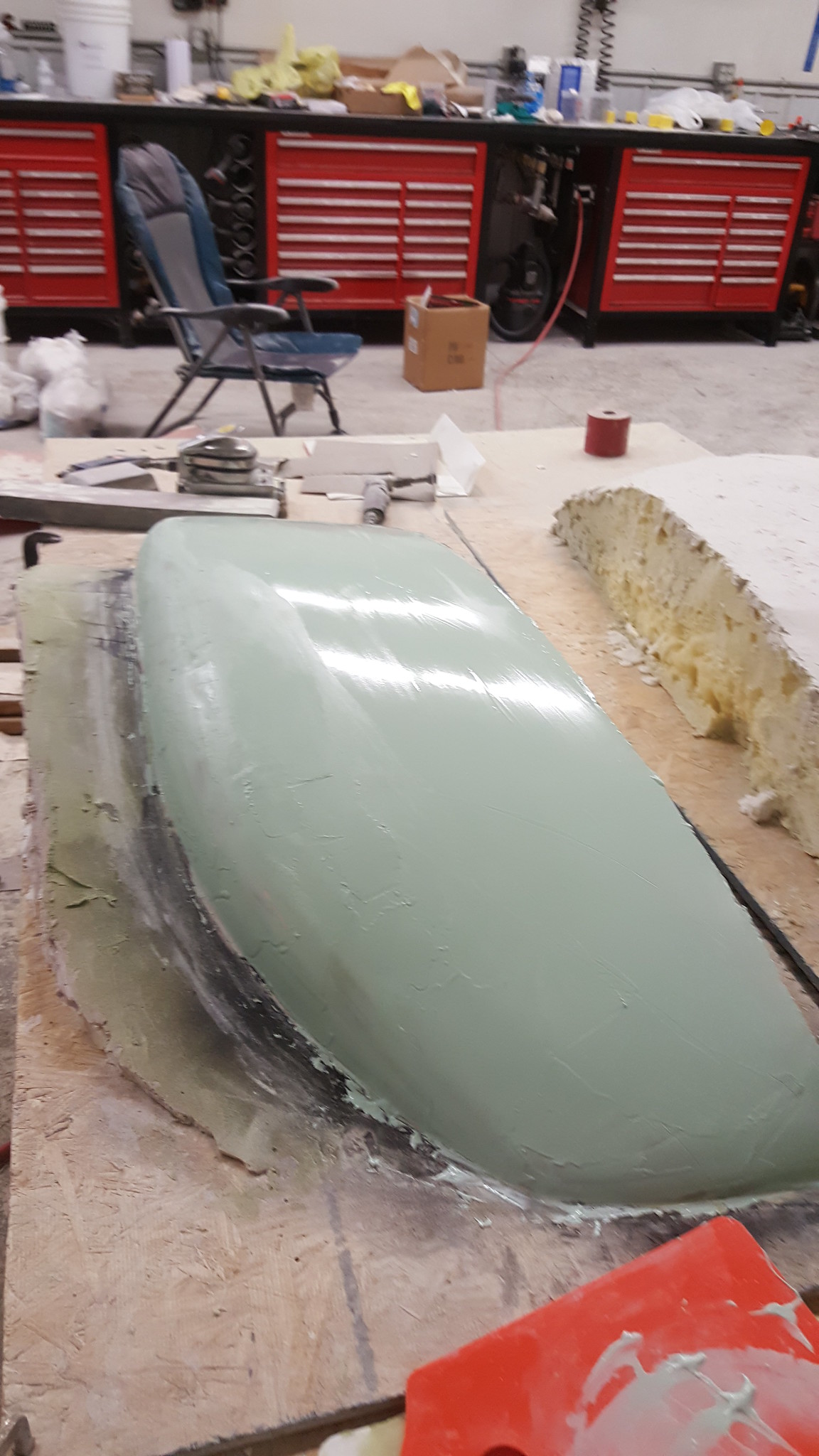

Went and bought a new gallon of primer and shot another coat on today, didn't crack like it did last time, but there are a few weird spots I'm going to have to figure out what to do with them.

Got the front shocks pulled out, measured and boxed up and ready to ship out to Bilstein next week. The way they measured out, going to remove the shock towers and try a set of the flat plates if I can get the reservoir hose up through them.

Since my wife is working this xmas eve, my son and I spent the evening out in the shop getting the transmission pulled out of the truck. Need to break it down and get the VB shipped off to Muldoons so he can do a little work on it. Also need to figure out what I burned up in it. The fluid was nice and burned. I did find that my zip tie that was holding the TV lever had come off, so I'm wondering if that might have been the cause of the issue. Going to make something that works better before I put it back in.

After 2nd coat, used too small of a tip and it shot really dry

Boxed up shocks, wonder if bilstein will love my flacking off paint....

Fenders scraped and sanded down

Tonight's primer coat

Compressor is working great now and the auto drain is working perfect.

Transfercase and transmission out of the truck