NakeDiesel

Smoke'n in the Mud

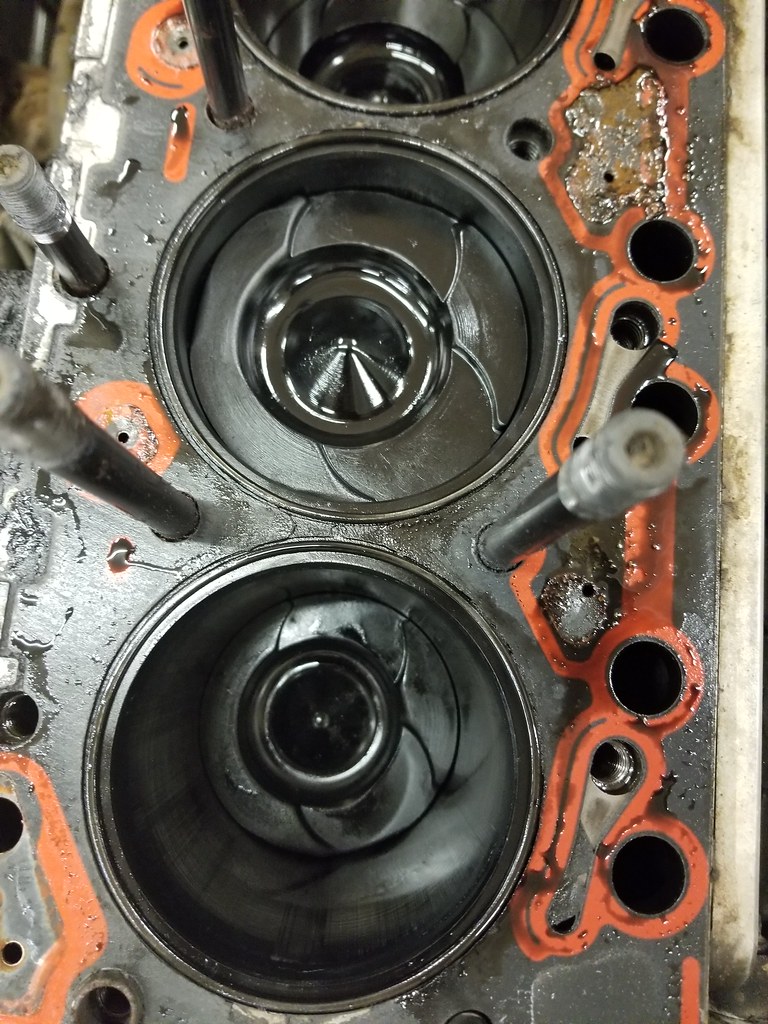

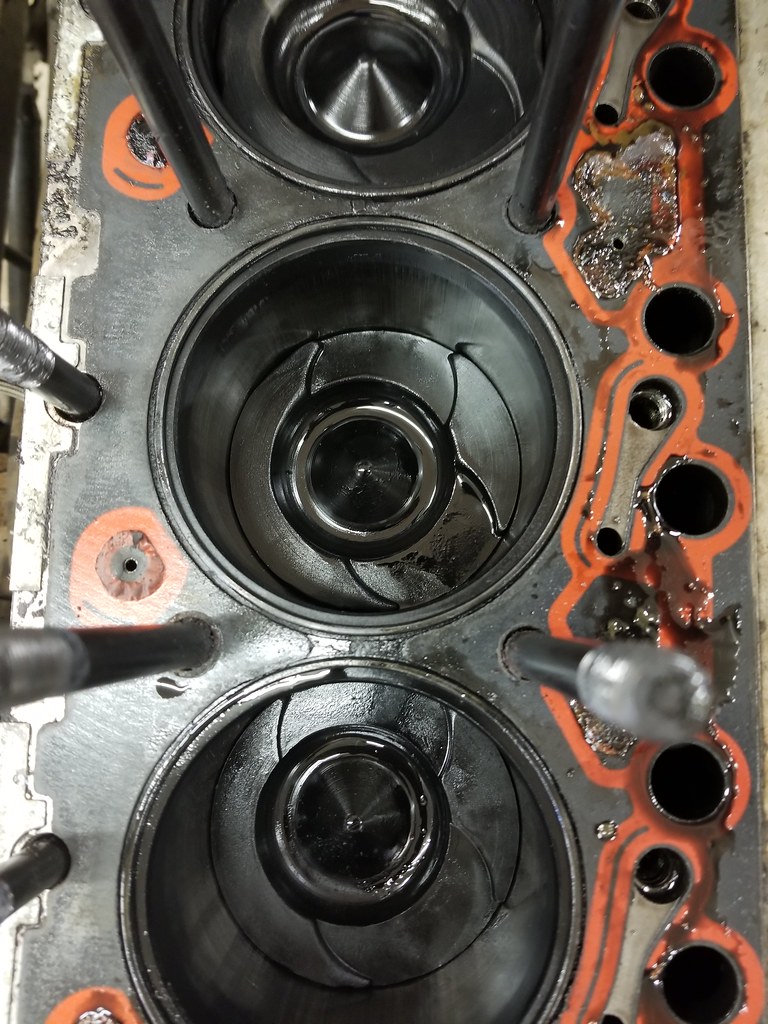

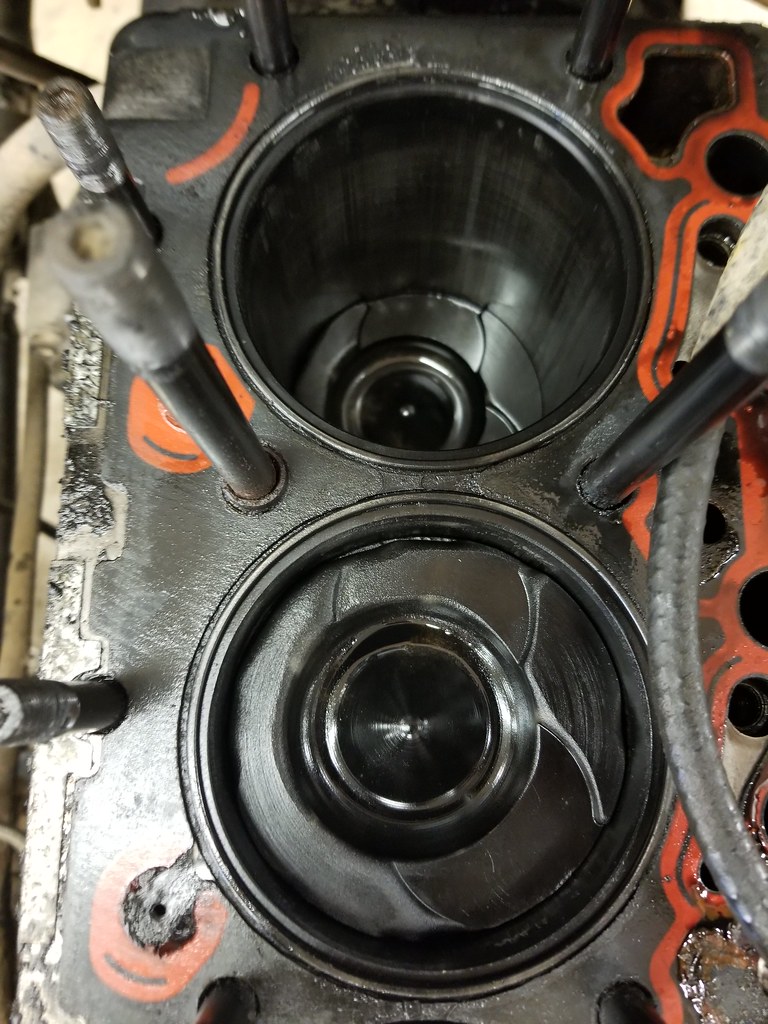

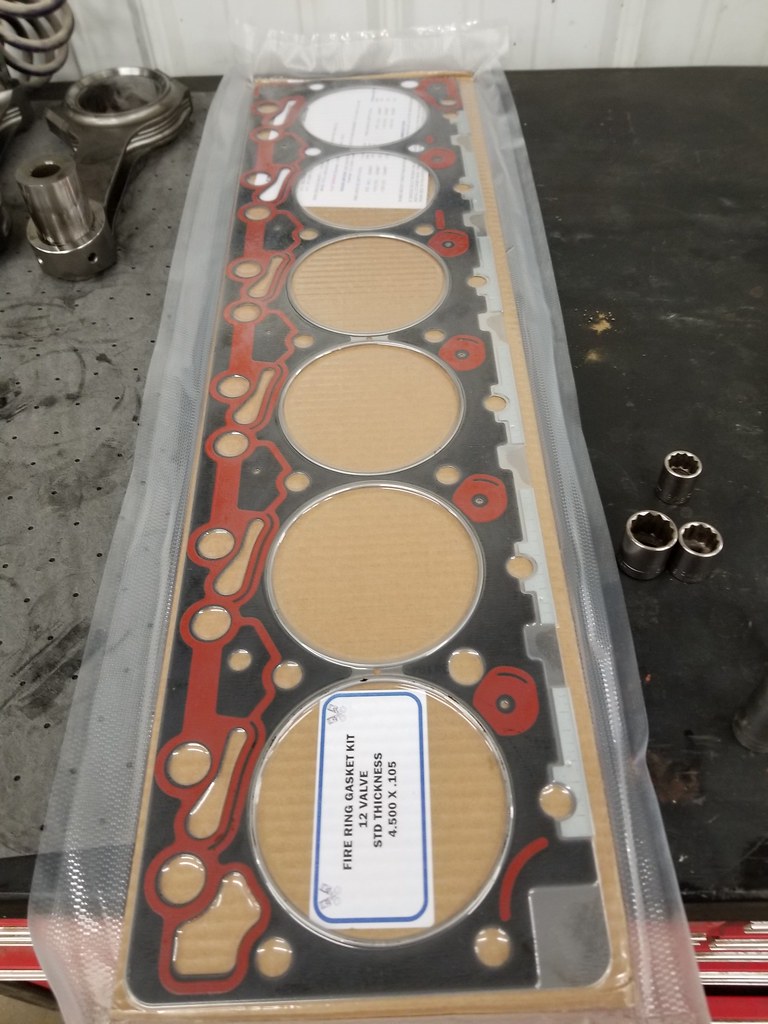

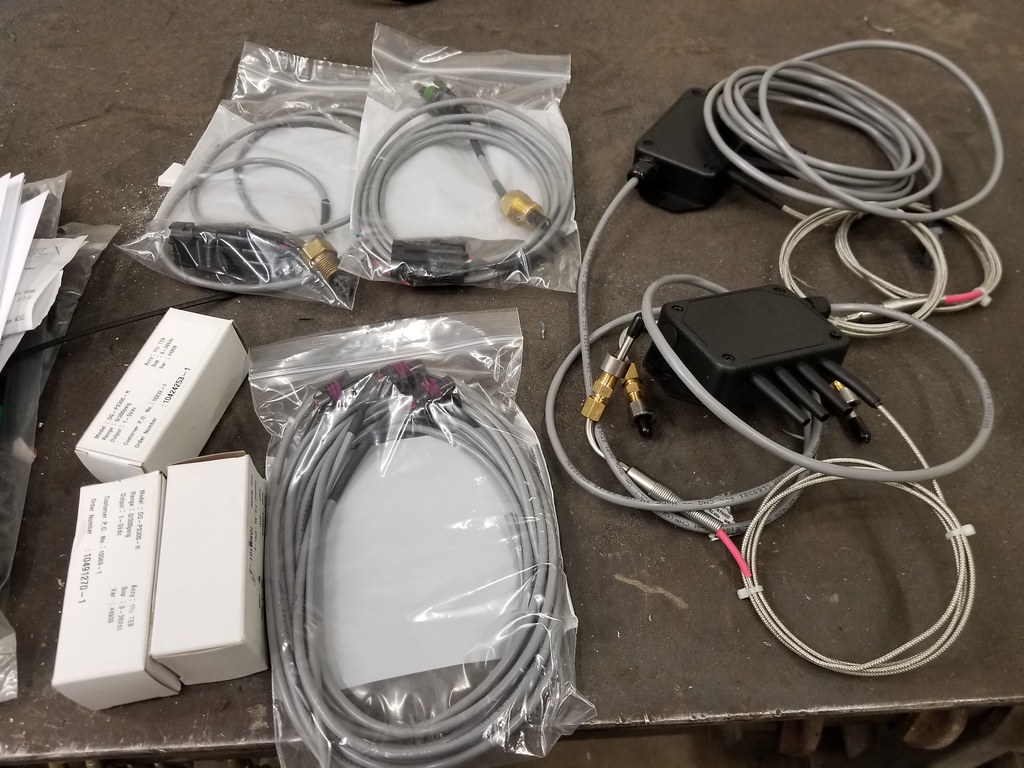

Pretty sure, going to check cylinders and injectors tomorrow when I'm off.

Had the best laugh tonight. Went to little nephews kindergarten graduation. They were dancing to some song and they were supposed to hold up 1 finger.... he flips off the whole crowd. We were all dying except his mom.

Sent from my SM-G955U using Tapatalk

Had the best laugh tonight. Went to little nephews kindergarten graduation. They were dancing to some song and they were supposed to hold up 1 finger.... he flips off the whole crowd. We were all dying except his mom.

Sent from my SM-G955U using Tapatalk