You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Stock truck build.

- Thread starter SuperSonic

- Start date

SuperSonic

El Vato

- Joined

- May 31, 2006

- Messages

- 2,036

Little by little. Should be working on it in the shop quite a bit this week, finally caught up with out of town work for a bit.

Last edited:

sledgehammer02

New member

- Joined

- Jun 28, 2012

- Messages

- 445

i think im in love

91dirtydiesel

IDIot

- Joined

- Jan 11, 2012

- Messages

- 461

Amazing fab work!

jeremy153624

New member

- Joined

- May 10, 2009

- Messages

- 565

Looks great! Amazing attention to detail! Subscribed

Fireman450

Daring to be diffrent!!

- Joined

- Nov 24, 2007

- Messages

- 1,606

Tick..... Tock....... Tick........ Tock  oke:

oke:

mpeters0991

New member

- Joined

- Feb 6, 2011

- Messages

- 271

Had anymore time to work on it? Has the engine been started yet to see if it will run?

Can't wait to see this thing spool up. Probably the coolest project I have seen yet!

Can't wait to see this thing spool up. Probably the coolest project I have seen yet!

kjpcummins

New member

- Joined

- Feb 15, 2009

- Messages

- 2,322

Ive been looking into a turbo merge collector like on your headers but a 6 into 1. Ive never had one in my hands but is there room to weld all the way around each of the pipes goin into the collector. Any advice on pipe size and the size of pipe they should collect into. This would be on a 5.9 cummins with a turbo mounted infront of the engine.

chevydiesellly

New member

- Joined

- Dec 6, 2008

- Messages

- 58

Just read the entire thread, thing is awesome. Thanks for sharing

SuperSonic

El Vato

- Joined

- May 31, 2006

- Messages

- 2,036

Ive been looking into a turbo merge collector like on your headers but a 6 into 1. Ive never had one in my hands but is there room to weld all the way around each of the pipes goin into the collector. Any advice on pipe size and the size of pipe they should collect into. This would be on a 5.9 cummins with a turbo mounted infront of the engine.

I got the collectors from Burns Stainless but there are a few other places out there that do good work.

I would recommend instead of a 6-1, to build a 6-2-1 setup.

You can order your collectors in different angles and separation. We have a micro torch for our tig for tight areas. It's a tight squeeze but you should be able to get 99% of it. We braise the inside of ours to ensure a perfect seal. I would recomend hat if you use any v band assemblies on high pressure exhaust, that you make/buy a stepped seal flange.

Primary tubes should be sized to not lose velocity. I used a 1.75 heavy wall 316 stainless for ours to a 2.5" collector outlet to a t6 flange.

On a 3.0 charger I would keep the mid pipes a little smaller.

SuperSonic

El Vato

- Joined

- May 31, 2006

- Messages

- 2,036

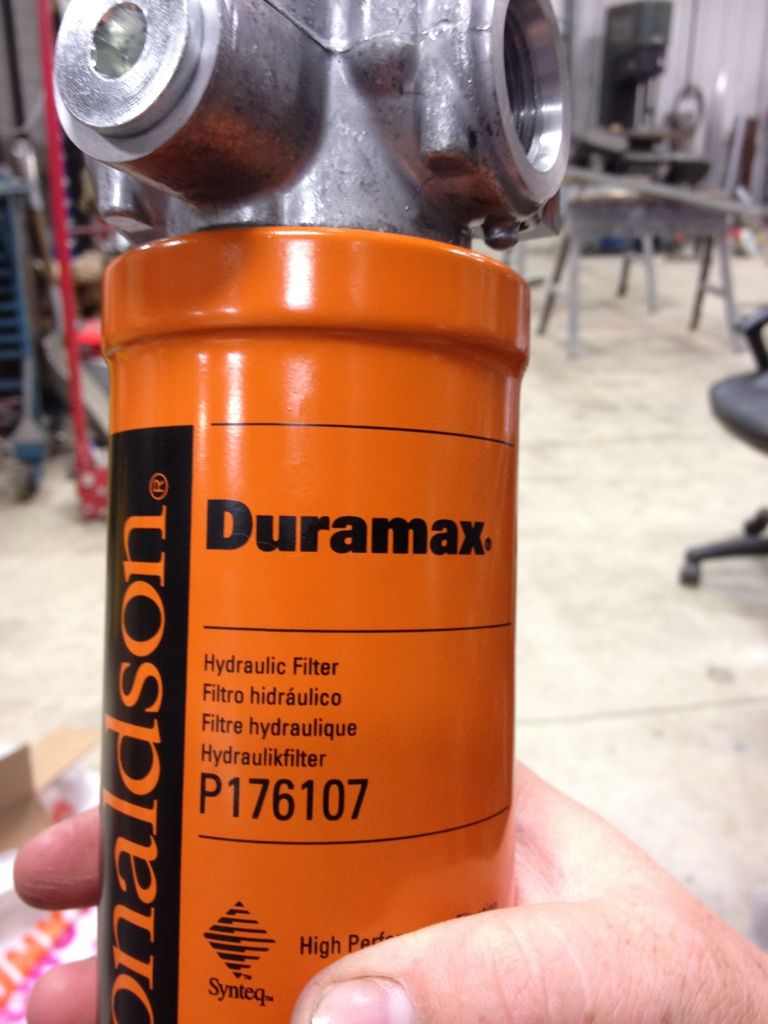

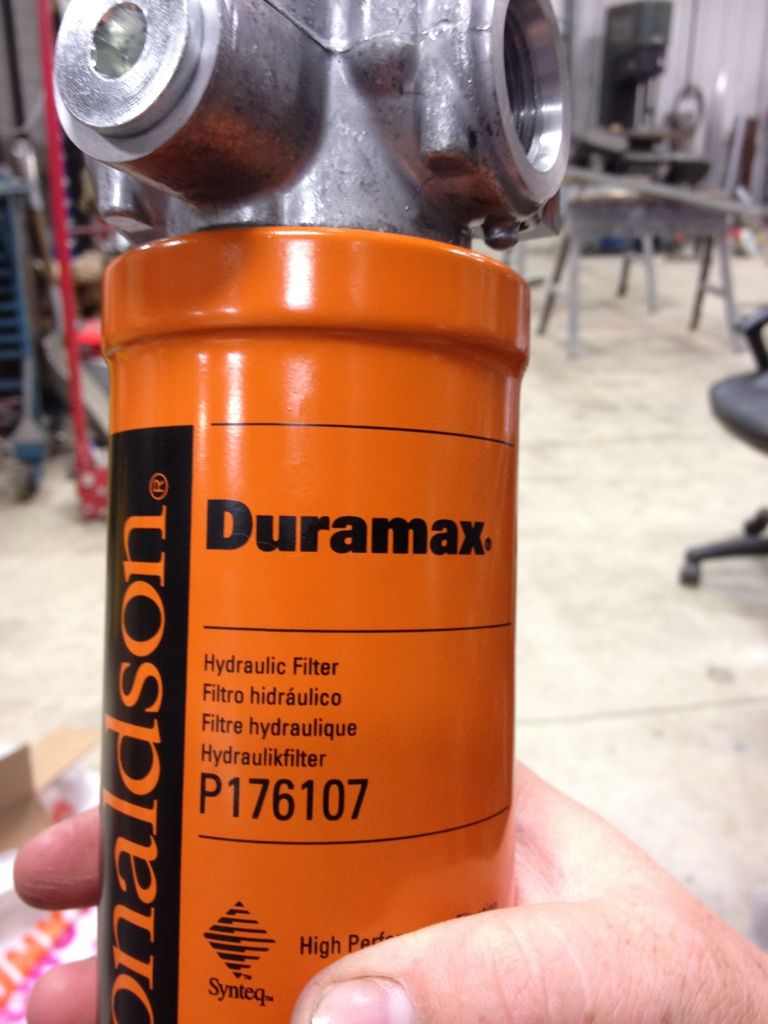

Donaldson hydraulic filter for the water injection system.

Convinient name.

Convinient name.