Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

I'll see what I can do, I know I won't be able to do it alone. Between it being a 1stgen and a stick, my hands are full just trying to keep myself in the cab. :lolly:

I'll stop by a buddies this week and see if he'll help me out.

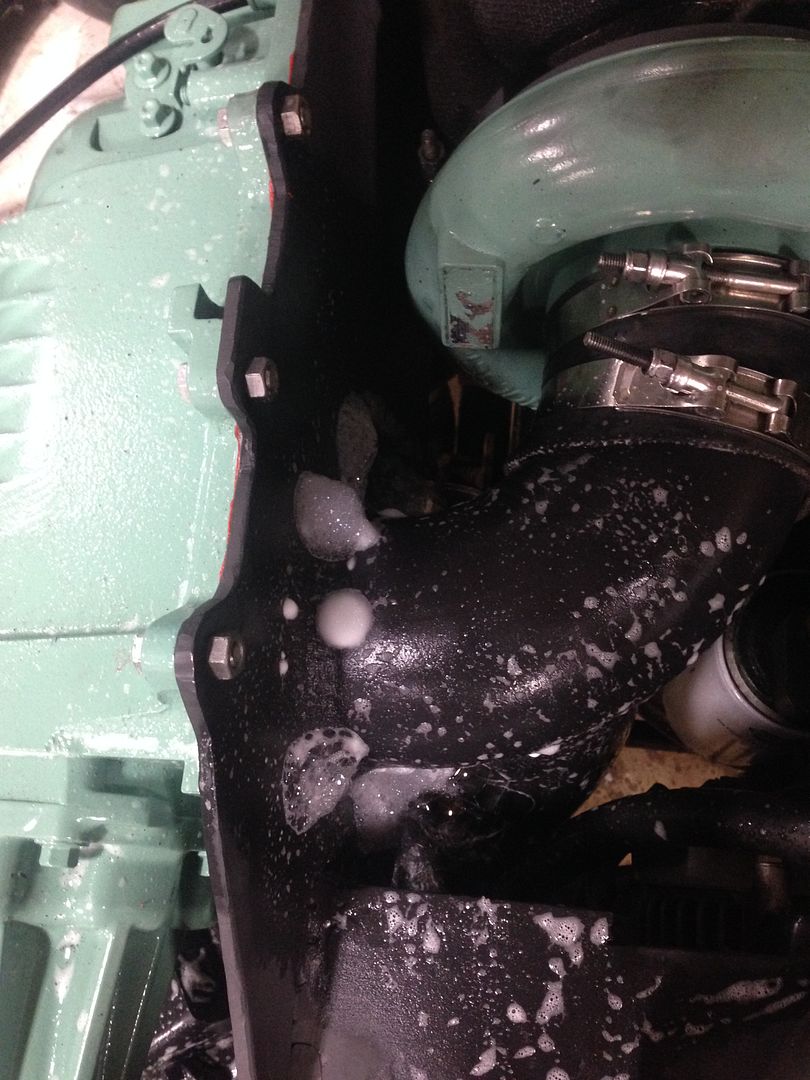

Also, that TB came with a couple return springs that I forgot about. They sit against those square stands and the throttle linkage. I'm going to see if I can use them instead of trying to find a mounting point for a normal return spring. Should help keep things tidy.

I'll stop by a buddies this week and see if he'll help me out.

Also, that TB came with a couple return springs that I forgot about. They sit against those square stands and the throttle linkage. I'm going to see if I can use them instead of trying to find a mounting point for a normal return spring. Should help keep things tidy.