You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Young gun's 94 build thread

- Thread starter YOUNG GUNS15

- Start date

biggy238

Active member

Multifaceted situation, but the truck I have experience with spools better, but also revs higher to move itselfI bet spool is more fuel related.

Sent from my iPhone using Tapatalk

Last edited:

Joesixpack

Pull'n it.

Spool is likely more cold weather related.

YOUNG GUNS15

Im AWESOME!!!!

Spence, were you running a 188 before?

No, I had a helix 2 that killed the thrust plate/retainer then went to a stock cam with a welded on gear to get me by for a while.

The cold does help a lot with spool, but with the way it reacts It's definitely a huge improvement. Feathering the throttle to bring up the charger is a thing of the past. Touch the throttle and it starts spooling on its own. Very fun setup to drive, ran it pretty hard yesterday with the comp cuts and it's just an animal.

YOUNG GUNS15

Im AWESOME!!!!

Every time I smash the go pedal and flip the lockup switch I am in complete awe of what this truck has become, this thing is an absolute blast!

On a side note I seem to have plugged some filters or something, after a hard 3rd gear full throttle run the truck just shut down and acted like it was out of fuel. Shutoff is pulling up and there is fuel at the filters. Haven't had much time to investigate.

On a side note I seem to have plugged some filters or something, after a hard 3rd gear full throttle run the truck just shut down and acted like it was out of fuel. Shutoff is pulling up and there is fuel at the filters. Haven't had much time to investigate.

YOUNG GUNS15

Im AWESOME!!!!

I need to stop updating from my phone, I dont understand why my pictures look fine on a PC one day then are super small thumbnails the next.

YOUNG GUNS15

Im AWESOME!!!!

Well I found out that I stuck the rack on my two week old 13mm, sounds like these things just happen more with 13mm pumps, Luckily the pump shop is taking care of it and I should be on the road at the end of the week!

YOUNG GUNS15

Im AWESOME!!!!

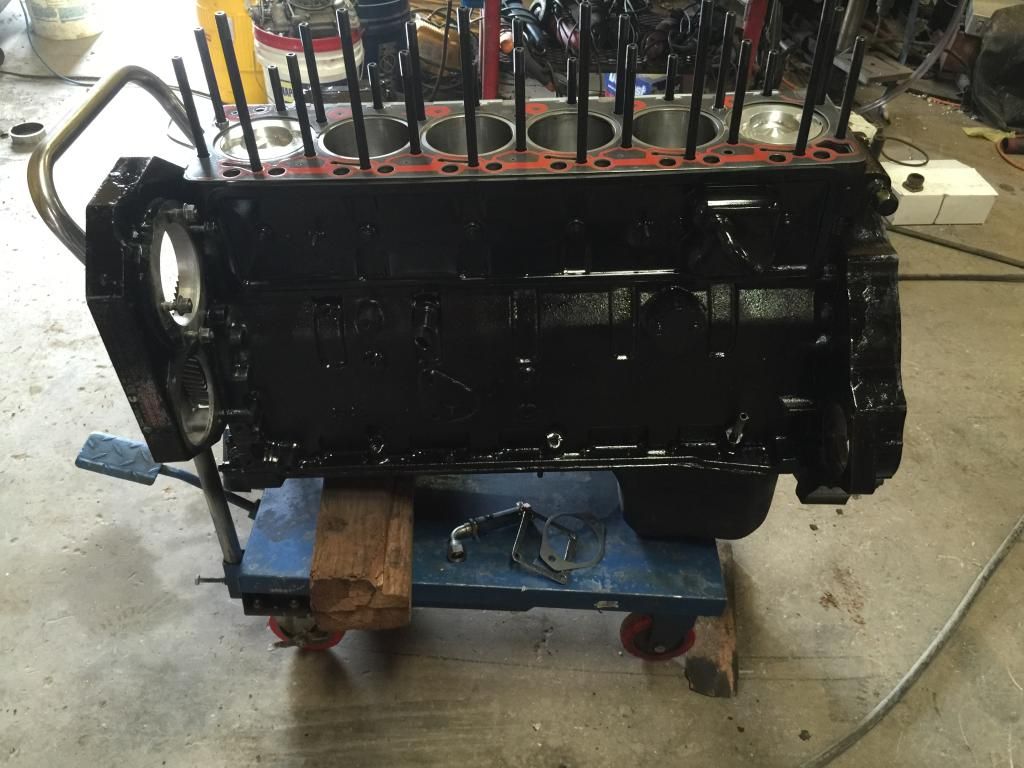

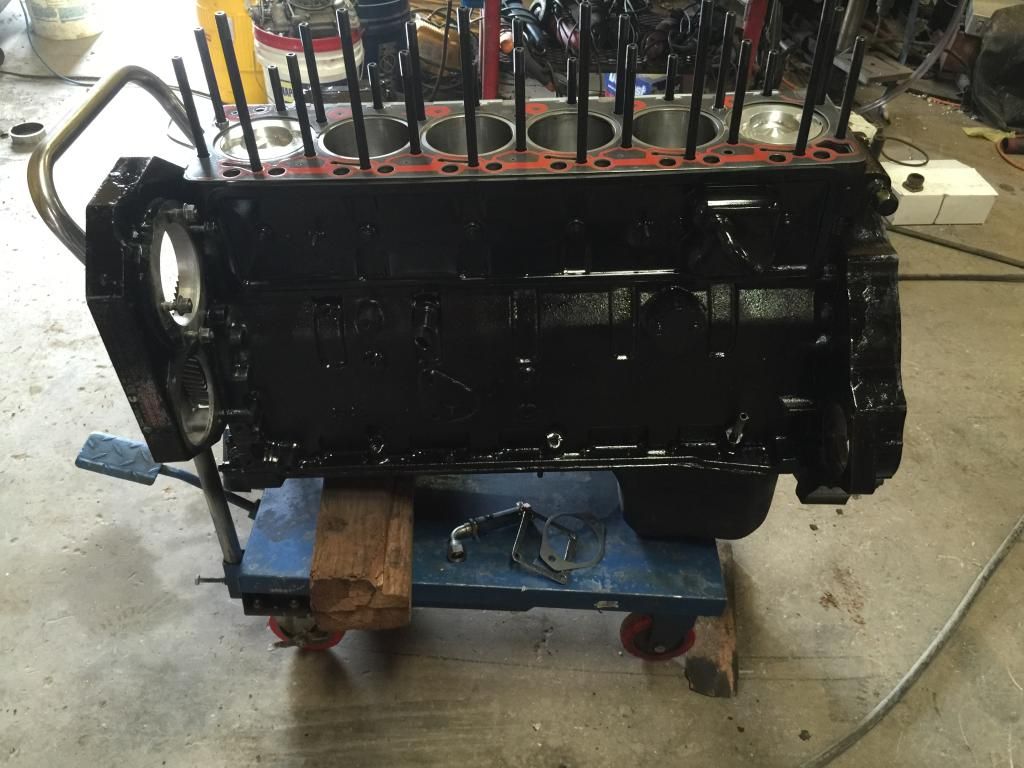

Updating my pictures, probably missed a few, but at least they are all full size now!

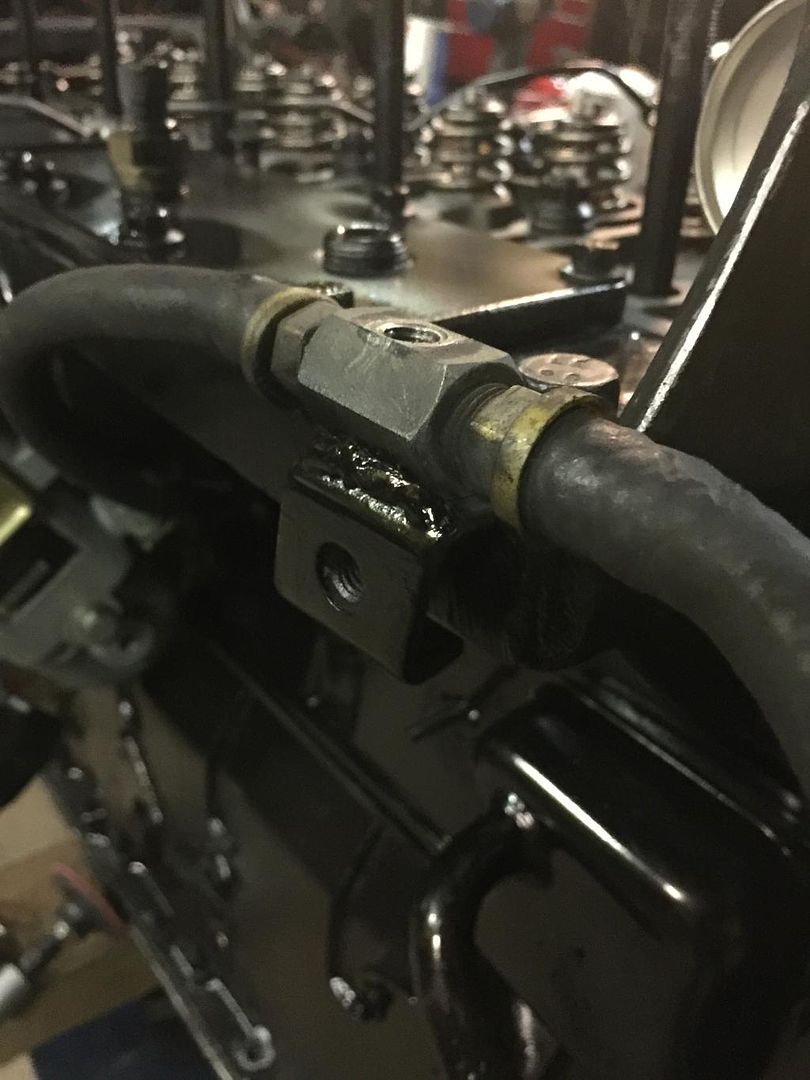

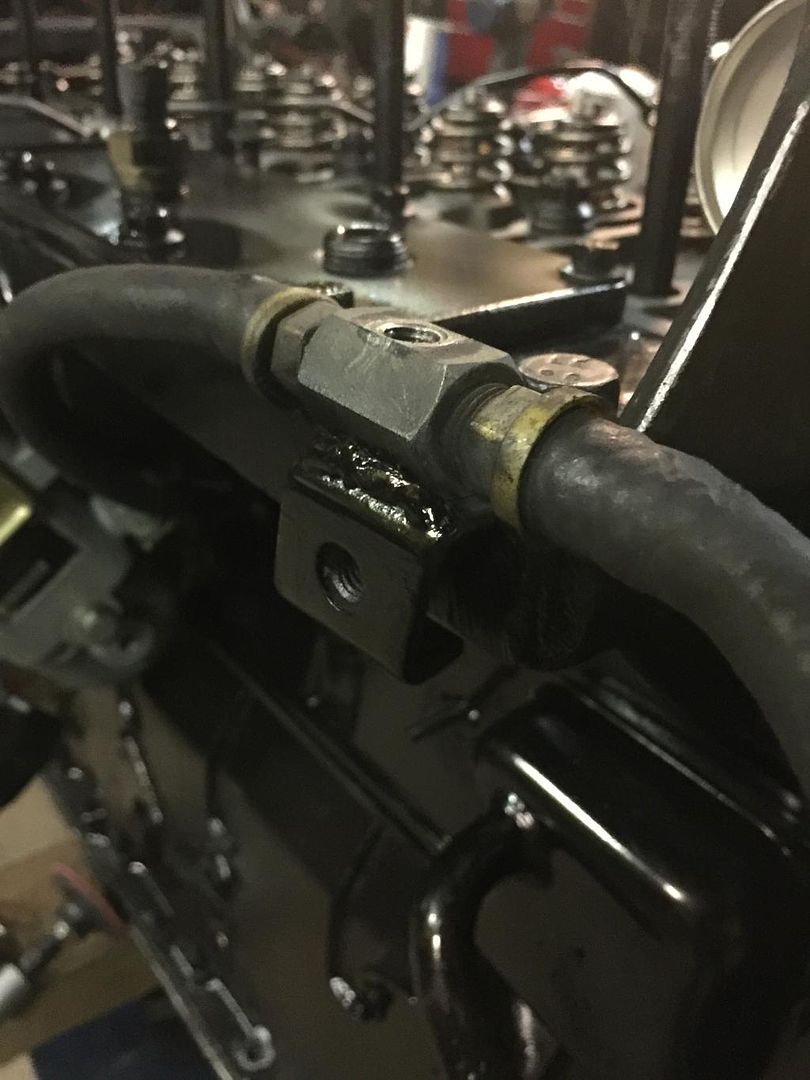

return fitting welded onto a bracket, I did this so it wasnt just hanging off the side of the motor anymore.

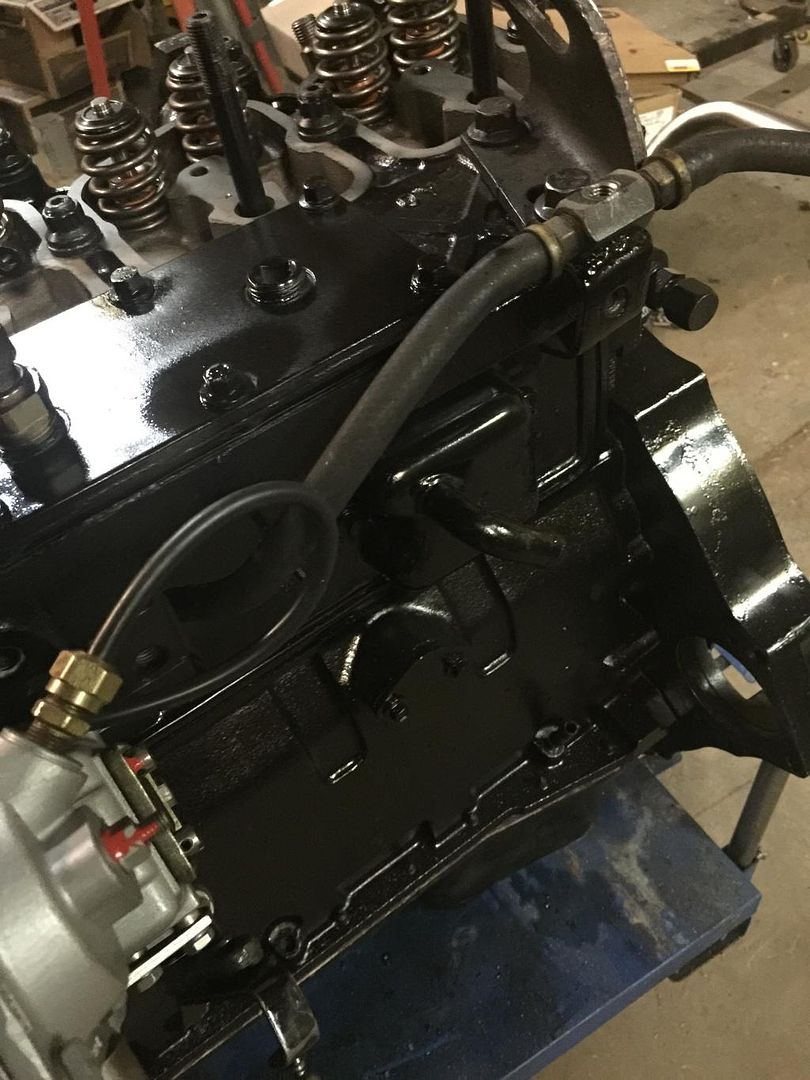

Manning pushrods! these are 3/8 .140 wall, very stout!

Cup end looks very nice

Ball end

Valve train assembled, head studs torqued to 125 ft lb

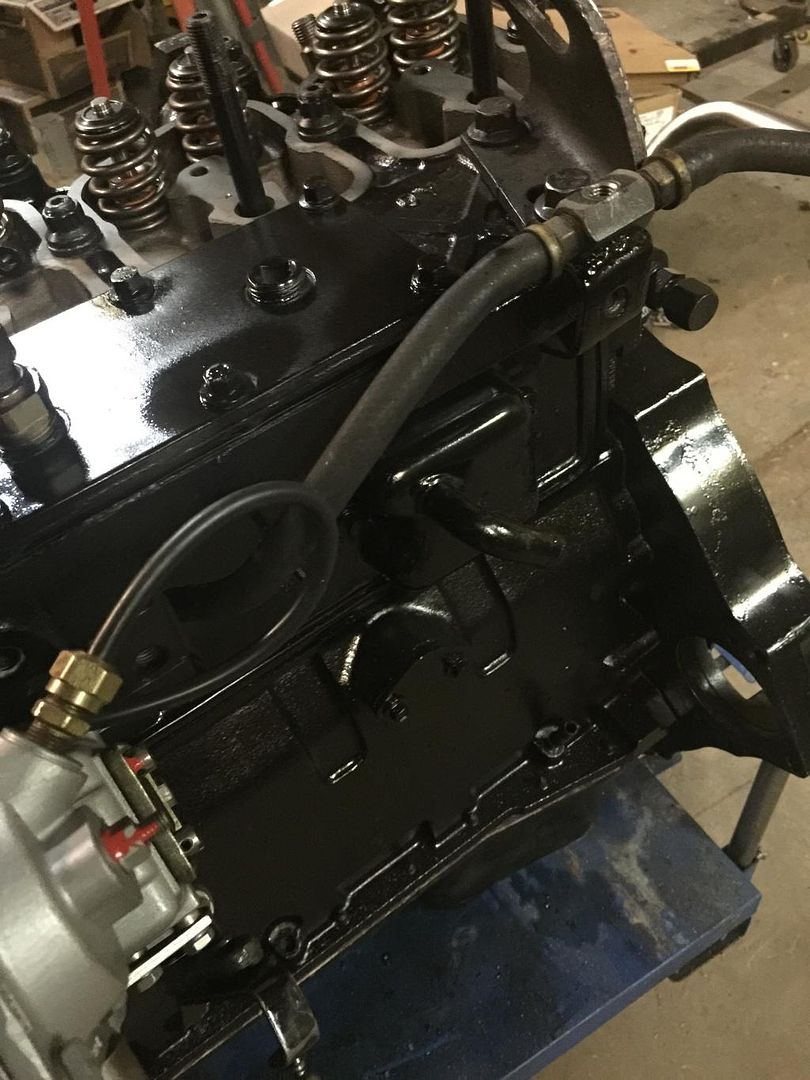

Injection pump timed to 18* for break in, ready for more accesories to be bolted on!

Turbo and injector lines

Its in!!

Little sunday drive the other day

return fitting welded onto a bracket, I did this so it wasnt just hanging off the side of the motor anymore.

Manning pushrods! these are 3/8 .140 wall, very stout!

Cup end looks very nice

Ball end

Valve train assembled, head studs torqued to 125 ft lb

Injection pump timed to 18* for break in, ready for more accesories to be bolted on!

Turbo and injector lines

Its in!!

Little sunday drive the other day

YOUNG GUNS15

Im AWESOME!!!!

Odds and ends left to do

-Swap gasser cluster for 6k RPM tachometer

-New fuel level sending unit install

-Wiring in the Dakota Digital SGI-5 box to get my speedometer back

-Painting the rest of my interior pieces black

-Fixing the sun visors (upohlstry shop mixed up the LH and RH visors and they dont fold down correctly)

For the most part those are the little things, here is what I have in mind in the next month for engine modifications/ Improvements.

-Build hx82 hot pipe/cold pipe, down pipe, support, and oil lines

-bolt on repaired 13mm pump

-tune with and without a plate (currently has a unknown manufacturer #8)

- Get my 5x.020, 145*, 300bar injectors refeshed

-set timing to a more conservative 24*

-Plumb coolant bypass

-install two stage nitrous system (TWO .145 solenoids!!)

Swap 1.10AR T4 housing for the dyno

-get an external waste gate setup (either 40mm or 50mm)

Right now I am still up in the air if I will actually run the hx82 setup, for now I want to build all the piping so it is ready to go on when I have more parts to support the massive flow the 102mm monster can put out (head work and intercooler). For the dyno Im going to leave the single on unless I get a wild hair and decided to leave the 102 on and make a few pulls.

-Swap gasser cluster for 6k RPM tachometer

-New fuel level sending unit install

-Wiring in the Dakota Digital SGI-5 box to get my speedometer back

-Painting the rest of my interior pieces black

-Fixing the sun visors (upohlstry shop mixed up the LH and RH visors and they dont fold down correctly)

For the most part those are the little things, here is what I have in mind in the next month for engine modifications/ Improvements.

-Build hx82 hot pipe/cold pipe, down pipe, support, and oil lines

-bolt on repaired 13mm pump

-tune with and without a plate (currently has a unknown manufacturer #8)

- Get my 5x.020, 145*, 300bar injectors refeshed

-set timing to a more conservative 24*

-Plumb coolant bypass

-install two stage nitrous system (TWO .145 solenoids!!)

Swap 1.10AR T4 housing for the dyno

-get an external waste gate setup (either 40mm or 50mm)

Right now I am still up in the air if I will actually run the hx82 setup, for now I want to build all the piping so it is ready to go on when I have more parts to support the massive flow the 102mm monster can put out (head work and intercooler). For the dyno Im going to leave the single on unless I get a wild hair and decided to leave the 102 on and make a few pulls.

madmikeismad

So mad

Your block is blacker than mine after all the oil ended up on the outside. Shiny.

YOUNG GUNS15

Im AWESOME!!!!

Your block is blacker than mine after all the oil ended up on the outside. Shiny.

This made me chuckle haha :rockwoot:

YOUNG GUNS15

Im AWESOME!!!!

Well I got the repaired 13mm on yesterday and it only made a handful of full throttle runs before it stuck the rack again, this time it was full throttle, I got it shut down but it toasted my forward clutch pack in the process. I need an air shutoff really bad.

12vCumminsFTW

Active member

Crap!! What's up with the rack sticking so much?

Sent from phone

Sent from phone

YOUNG GUNS15

Im AWESOME!!!!

The first time it hung the rack it was partially my fault, I installed new delivery valves, and I unknowingly reused a non-reusable crush washer that they had installed under the delivery valves, the washer for some reason came off center and got crushed into a stepped frisby looking thing. The pump shop was able to replace one p&b and save the rest. I think the others weren't damaged but off just enough to hang. So far they took care of me on the last pump. Although that was just labor and one p&b, don't know if it's going to take all 6 now to make it last.

On edit: I'll point out that I ALWAYS remove the washers under delivery valves, that said when I changed delivery valves I didn't see any copper, I figured since I had 131 seats that they left them out. The new crush washers are steel and they blended in good enough I couldn't tell they were in there.

On edit: I'll point out that I ALWAYS remove the washers under delivery valves, that said when I changed delivery valves I didn't see any copper, I figured since I had 131 seats that they left them out. The new crush washers are steel and they blended in good enough I couldn't tell they were in there.

Last edited:

What delivery valve holders are you running. Years back I bought a 13mm pump of here that hung the rack after a few runs, had it repaired and did it again. After that I sent it to northeast diesel and was told the stock holders were one of the main reasons for the problem, to much of a restriction.

97rada

New member

The first time it hung the rack it was partially my fault, I installed new delivery valves, and I unknowingly reused a non-reusable crush washer that they had installed under the delivery valves, the washer for some reason came off center and got crushed into a stepped frisby looking thing. The pump shop was able to replace one p&b and save the rest. I think the others weren't damaged but off just enough to hang. So far they took care of me on the last pump. Although that was just labor and one p&b, don't know if it's going to take all 6 now to make it last.

On edit: I'll point out that I ALWAYS remove the washers under delivery valves, that said when I changed delivery valves I didn't see any copper, I figured since I had 131 seats that they left them out. The new crush washers are steel and they blended in good enough I couldn't tell they were in there.

What is the purpose Of the washers? I have only ever found the washers one time and I left them in.