Whew, just read through this whole thread! A lot of very good info, :thankyou2:

Thinking about doing bars for quite a while, heres what I had planned.

This is a daily driver, maybe a sled pull or two, and a run or two down the 1/4 mile, but no more than that.

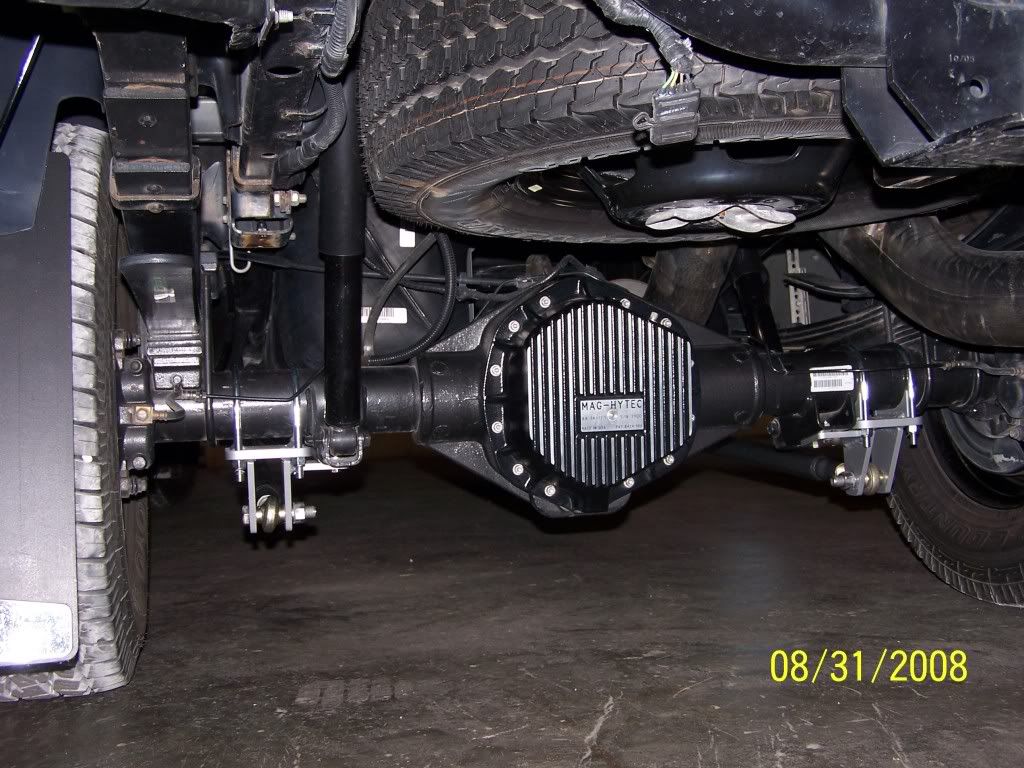

I'm also planning to do something to soften the rear, possibly mounting the spring shackles on an air bag supported crossmember (see Kelderman). I've even debated eliminating the springs and building a 4 link, air bag system.

I plan to make a bracket to bolt on the bottom of the u-bolts, and run a single bar to the slight angle drop of the frame bottom about where the front bed/back cab is, about 66". Heard about the tractor supply links, noticed there are different ratings and sizes, and planned to use the category II, type with 3/4" bolts.

You can also get heims and inserts from any speed/race car shop, better quality, a bit more cash.

Now, where the spring end heim mounts would be important, due to the spring travel arc, and since the lift block is actually tilted forward, I planned to move that mount rearward from axle center, and/or drop it a little. The longer that bracket is, the more leverage and effect it will have, any input?

It would be great if someone with the proper software could plot the spring arc.

Heres what I've heard elsewhere:

"The A-arm style rides too rough for the street" That comment was echo'd here.

"Weld the axle tubes, or the center section will spin" Any input there?

"Make the bars the same angle as the driveshaft" Yes/no, doesn't matter?

Once again :thankyou2: great info here.

![2009-06-18%2006.10.26[1].jpg](/data/attachments/14/14521-49ad99e84959c1ee2d28b0b6e6a222ca.jpg)

![2009-06-18%2006.10.14[1].jpg](/data/attachments/14/14520-99e8928f5e5c70d29c84a1e1d3b31d60.jpg)