You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Supercharger pulley

- Thread starter Tacoclaw

- Start date

Mark Nixon

No Savior among the flesh

- Joined

- Feb 26, 2009

- Messages

- 8,677

Sometimes it is amazing the crap you'll put yourself, through, Levi.

I've ridden in Carl's truck and I have to say, it's a pleasant blend of "easy cruising" and "Holy Sh!t, don't hit that!" LOL

Pretty well-mannered for being visually intimidating.

Mark.

I've ridden in Carl's truck and I have to say, it's a pleasant blend of "easy cruising" and "Holy Sh!t, don't hit that!" LOL

Pretty well-mannered for being visually intimidating.

Mark.

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

If the CR balancer is any bigger in diameter than mine it won't be an option. There was barely enough room to fit the belt between my pulley and it before I cut the grooves, I'm not sure you could get a belt between them once the blower belt is in its grooves. I do wonder what the diameter of a fluidampr or the other brand is, I've always wanted to get one and see if it cut down on interior rattles with my poly mounts...

Cool info though.

Anything for the love of an old truck, Mark. I'm really just doing this stuff to keep my hands busy, keeps me outside and off the Xbox. :doh:

I am hoping it makes the old turd a little more driveable, with the ported head and cam it spools the HX52 ok but it could be a lot better. It'd be nice to be able to take gaps in traffic without having to worry about looking like an idiot. :lolly:

Cool info though.

Anything for the love of an old truck, Mark. I'm really just doing this stuff to keep my hands busy, keeps me outside and off the Xbox. :doh:

I am hoping it makes the old turd a little more driveable, with the ported head and cam it spools the HX52 ok but it could be a lot better. It'd be nice to be able to take gaps in traffic without having to worry about looking like an idiot. :lolly:

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

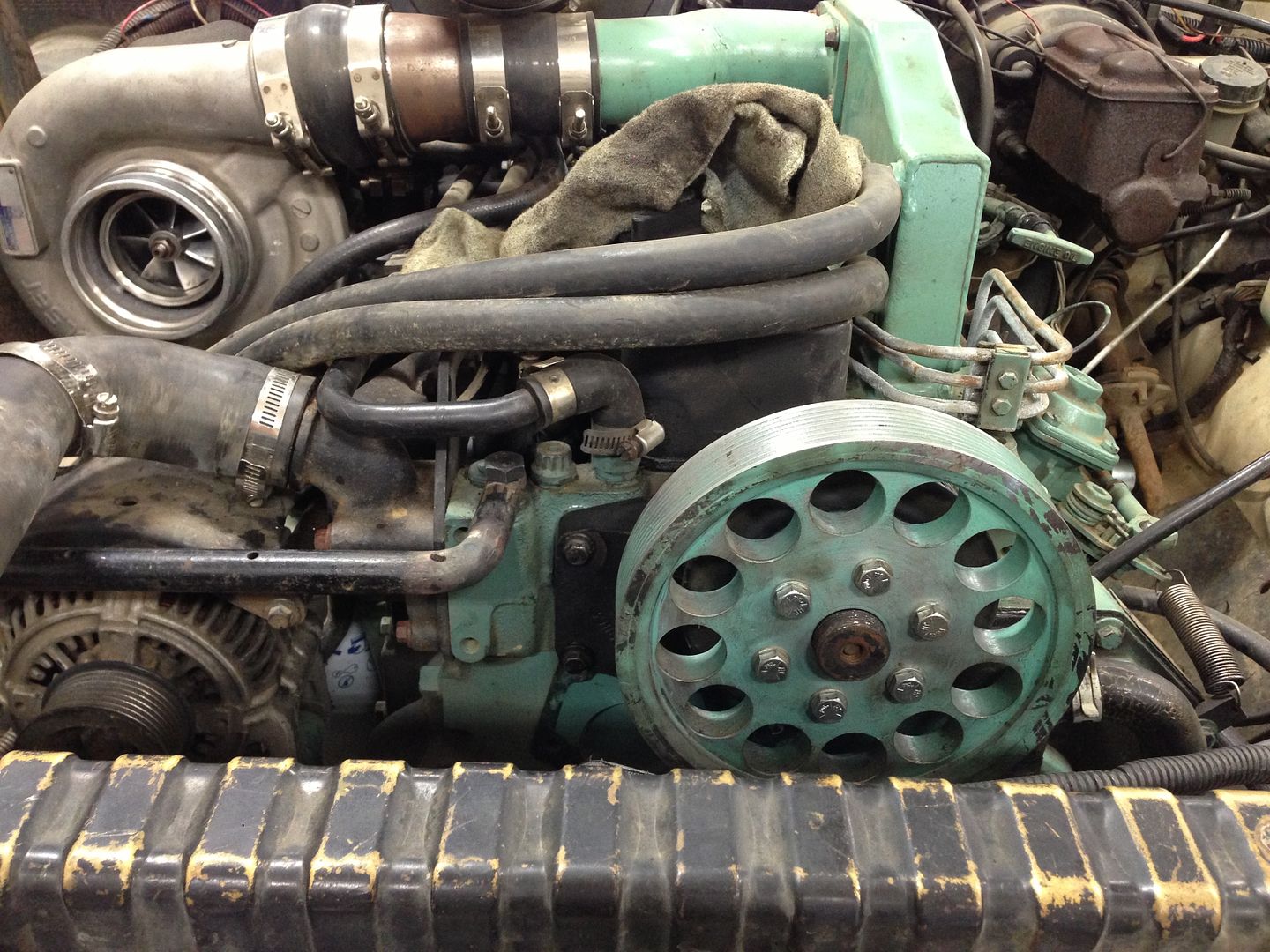

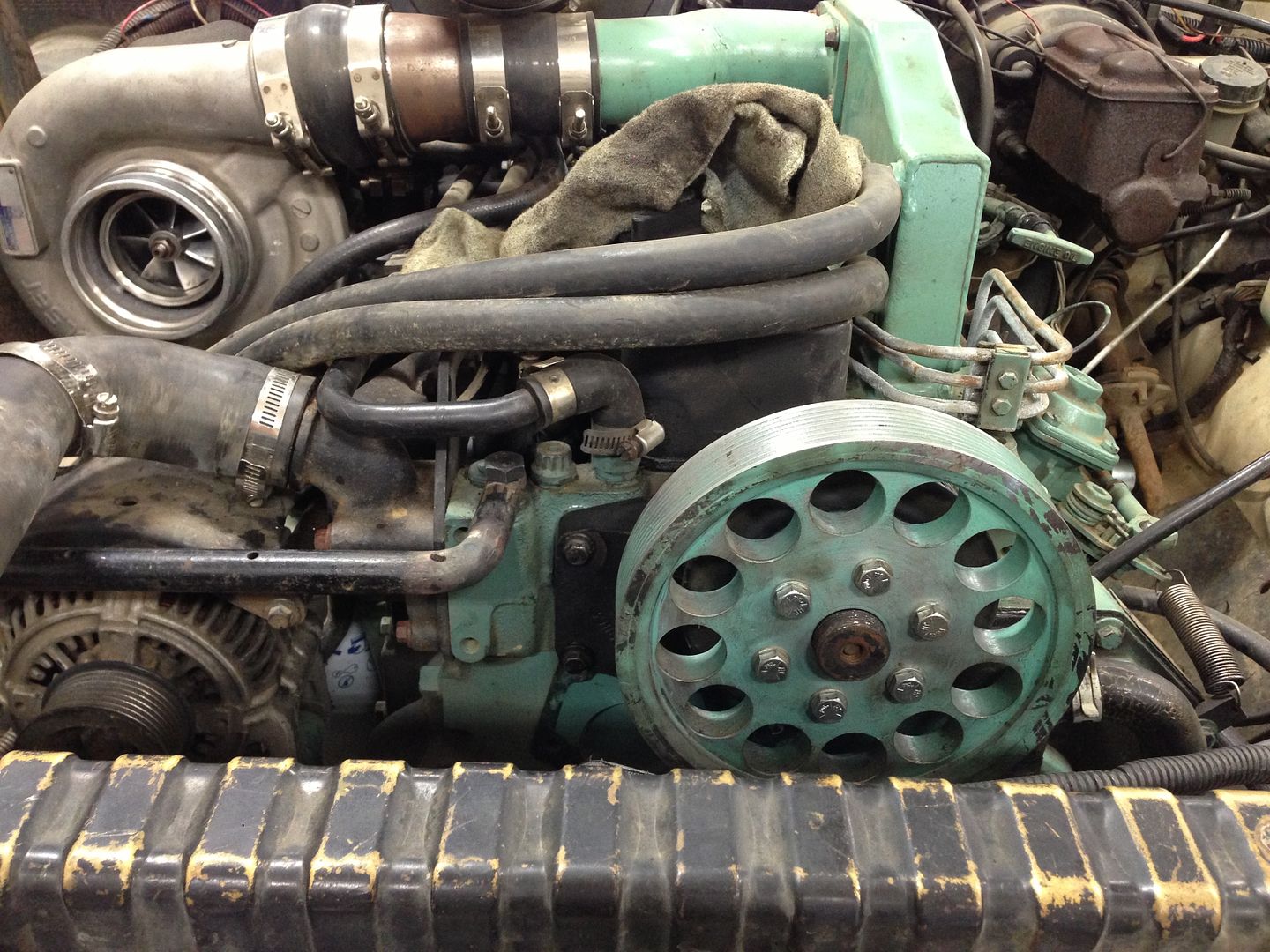

Sooo, has anyone messed around with turning their fan hub? I've been contemplating this belt routing (and failing) so I went to my old fallback of just taking things apart until I figure it out. I pulled the fan hub off and noticed the holes on the head are the same distance apart as the top holes of the idler. Did some spinning and flopping and came up with this, which, if I followed the old belt routing, would give me ~1/2 of the pulley surface engagement.

Is it safe to drill and tap the head in the area of those existing holes? I may just try to drill through the idler bracket and match up with the other two existing holes that are there if I can, just wondering if anyone has seen anybody else messing with this so I can see what they did. (Steal their ideas)

I may have to put a guard on that pulley to satisfy MSHA though. :lolly :

Is it safe to drill and tap the head in the area of those existing holes? I may just try to drill through the idler bracket and match up with the other two existing holes that are there if I can, just wondering if anyone has seen anybody else messing with this so I can see what they did. (Steal their ideas)

I may have to put a guard on that pulley to satisfy MSHA though. :lolly :

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

Also, Carl, I noticed you mentioned another A/W cooler. I've got that one plumbed I to a separate water system that circulates from the old washer reservoir and through an AC condensor in the front, are you worried that it wouldn't be able to take the combined heat or that the blower's constant heat may stress the turbo?

I've got a frozenboost 'cooler I used to run on my twin setup, I could try to find some room for it up there but real estate will be getting tight with the air filter up there as well.

I've got a frozenboost 'cooler I used to run on my twin setup, I could try to find some room for it up there but real estate will be getting tight with the air filter up there as well.

TURBOLVR

Mr. Whipple

- Joined

- Mar 23, 2008

- Messages

- 2,566

I wouldnt drill the head. You could just add an idler down where the AC goes and change the routing to get better wrap.

I mentioned the cooler because I noticed you already had one and the lightnings had them stock. The eatons are commonly called "heatons" because they have a tendency to make hot air.

I mentioned the cooler because I noticed you already had one and the lightnings had them stock. The eatons are commonly called "heatons" because they have a tendency to make hot air.

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

Heh, I actually machined off the bosses for the factory Cobra heat exchanger. I didn't like the extra 2" thick it made it and once I started pricing them I knew that sucker wasn't going to be on my truck. LOL

I just ditched it so I could use a flat plate for the mount. I'll look into some more cooling once this thing is functioning. It may work well enough for me the first time I hook it up and I won't change a thing.

I just ditched it so I could use a flat plate for the mount. I'll look into some more cooling once this thing is functioning. It may work well enough for me the first time I hook it up and I won't change a thing.

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

Turns out my fan mount finding wasn't so revolutionary, there's a thread over in 4BTswaps where someone mentions that very thing. Such is the Internet I guess, someone's already done everything, you've just got to find it.

Spent the evening drinking and searching around for gam idler info. Info is pretty slim, but I did find Dayco's "heavy" line of tensioners. They're all at least 8-rib, and being Dayco I'm assuming our local Carquest can get them in next-day (and cheaper than the Vortech ones listed earlier). I'll give them a call and confirm in a bit.

Dayco Mobile

^mobile site, I have no idea how to link their normal site off my phone, it's way different than the mobile setup. =\

:edit: Just look up numbers 89103 for the smallest, ribbed steel and 89105 for the smallest, smooth steel.

They have poly as well, but meh.

Spent the evening drinking and searching around for gam idler info. Info is pretty slim, but I did find Dayco's "heavy" line of tensioners. They're all at least 8-rib, and being Dayco I'm assuming our local Carquest can get them in next-day (and cheaper than the Vortech ones listed earlier). I'll give them a call and confirm in a bit.

Dayco Mobile

^mobile site, I have no idea how to link their normal site off my phone, it's way different than the mobile setup. =\

:edit: Just look up numbers 89103 for the smallest, ribbed steel and 89105 for the smallest, smooth steel.

They have poly as well, but meh.

Last edited:

TURBOLVR

Mr. Whipple

- Joined

- Mar 23, 2008

- Messages

- 2,566

try this one: MOTORCRAFT BELT IDLER PULLEY YS286

I mentioned the vortech because it has shoulders to keep the belt in alignment.

If you do not use a substantial bypass and throw a belt, the truck will shut down.

Now that I have said that, I have never thrown a belt...but I do remove them occasionally just to see the difference.

I mentioned the vortech because it has shoulders to keep the belt in alignment.

If you do not use a substantial bypass and throw a belt, the truck will shut down.

Now that I have said that, I have never thrown a belt...but I do remove them occasionally just to see the difference.

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

I see, this is my first time dealing with a belt system. I just assumed if I got my pulleys aligned I wouldn't have tracking problems, are you saying I may possibly need a toothed idler regardless?

I do realize it's hanging quite a ways off the engine, I just figured with a tensioner and a couple flat idlers to keep it wound around everything I would be fine. I also didn't see how you could use an inside idler without pulling the belt away from your intended pulleys, unless you threw an outside idler on each side of it. I'll look into it, as of right now you've got me more interested in getting my factory belt sorted before I worry too much about the blower belt.

I actually bought a Chinese, 98mm LS1 throttle body off EBay to try to use as a bypass. I figure I could sand the butterfly to fit slightly loose then use the Eaton's bypass actuator to work it and disable its factory 32mm deal. It's all just theory right now but if I end up needing it with the HX sucking too much I could wire it open and limp along I think.

Thanks again for the thoughts, Dayco had a flanges internal pulley but it's bigger than I want to try to wrangle into my setup. :thankyou2:

I do realize it's hanging quite a ways off the engine, I just figured with a tensioner and a couple flat idlers to keep it wound around everything I would be fine. I also didn't see how you could use an inside idler without pulling the belt away from your intended pulleys, unless you threw an outside idler on each side of it. I'll look into it, as of right now you've got me more interested in getting my factory belt sorted before I worry too much about the blower belt.

I actually bought a Chinese, 98mm LS1 throttle body off EBay to try to use as a bypass. I figure I could sand the butterfly to fit slightly loose then use the Eaton's bypass actuator to work it and disable its factory 32mm deal. It's all just theory right now but if I end up needing it with the HX sucking too much I could wire it open and limp along I think.

Thanks again for the thoughts, Dayco had a flanges internal pulley but it's bigger than I want to try to wrangle into my setup. :thankyou2:

TURBOLVR

Mr. Whipple

- Joined

- Mar 23, 2008

- Messages

- 2,566

by the nature of belt stretch and the fact we use spring tensioners, the belt can get slack and jump. flat pulleys will not prevent or correct this.

the vortech is a smooth but shouldered pulley. It keeps the belt from wandering.

Since you have access to a lathe, it may be worth your while to simply cut a center groove in the smooth pulley of your choice (material allowing).

toothed pulleys are for the inside and would be used for such things as replacing the AC to get better wrap on the crank as it allows a different routing.

as for the throttle body, I have one for a mustang too! I didnt use it as they have air bleeds and leaks that would cause pressure drops. I also needed a valve that would work without a controller, as any form of actuator would add complication and delay.

the vortech is a smooth but shouldered pulley. It keeps the belt from wandering.

Since you have access to a lathe, it may be worth your while to simply cut a center groove in the smooth pulley of your choice (material allowing).

toothed pulleys are for the inside and would be used for such things as replacing the AC to get better wrap on the crank as it allows a different routing.

as for the throttle body, I have one for a mustang too! I didnt use it as they have air bleeds and leaks that would cause pressure drops. I also needed a valve that would work without a controller, as any form of actuator would add complication and delay.

Last edited:

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

Yeah, this LS one has a bunch of ports as well, I figure I'll just be going wild with a pipe tap and plugging them all. The blower itself isn't lacking for random ports drilled in it either. :doh:

I see what you're saying now, if the engine rolled backwards or something faster than the tensioner could react it wouldn't take much for the belt to get crooked on one of those flat

pulleys pretty easily. Cool deal, I'll go ahead and plan to incorporate a pulley with the flanged OD opposite the tensioner side of the belt.

On the actuator I actually used, and still have, a variable pressure switch and 12v air spool I used to actuate my external wastegate on my twins. No real reason for it, I just found it easier/cleaner to run wires than air hoses, but it wasn't bad to work with. Probably be a quick, easy way for me to get things working.

Honestly, for the work and RPMs this thing sees I may not need a bypass at all. I'm still going to leave room for it in the piping though, just in case.

I see what you're saying now, if the engine rolled backwards or something faster than the tensioner could react it wouldn't take much for the belt to get crooked on one of those flat

pulleys pretty easily. Cool deal, I'll go ahead and plan to incorporate a pulley with the flanged OD opposite the tensioner side of the belt.

On the actuator I actually used, and still have, a variable pressure switch and 12v air spool I used to actuate my external wastegate on my twins. No real reason for it, I just found it easier/cleaner to run wires than air hoses, but it wasn't bad to work with. Probably be a quick, easy way for me to get things working.

Honestly, for the work and RPMs this thing sees I may not need a bypass at all. I'm still going to leave room for it in the piping though, just in case.

Tacoclaw

New member

- Joined

- Sep 29, 2011

- Messages

- 453

Nah, I let it air-cool for the next 24 hours and ground off the biggest chunks of slag I found, that annealed it and it cut like butter. :rockwoot:

I was taking .200 passes anyways once I got the highest spots knocked down. Once you get that much of the cutter engaged it mellows a lot of the typical chattering and howling out.

I was taking .200 passes anyways once I got the highest spots knocked down. Once you get that much of the cutter engaged it mellows a lot of the typical chattering and howling out.