Zeppelin654

New member

- Joined

- Nov 11, 2011

- Messages

- 843

Plans as of now for the next build:

- 12V block. honed, decked, tapped for 14 mm mains

- arp 14 mm mains

- arp 12 mm 625 head studs

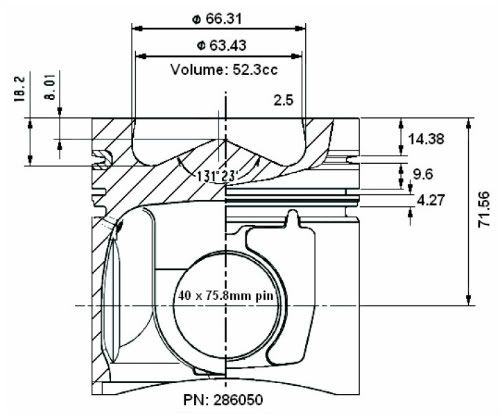

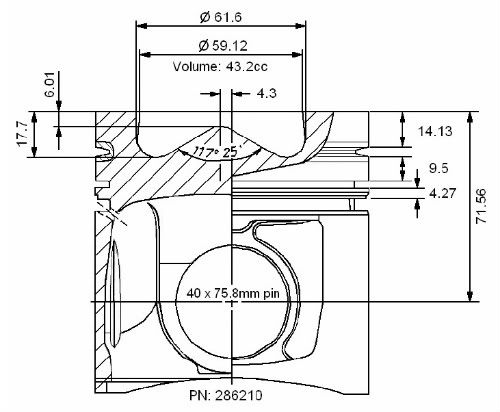

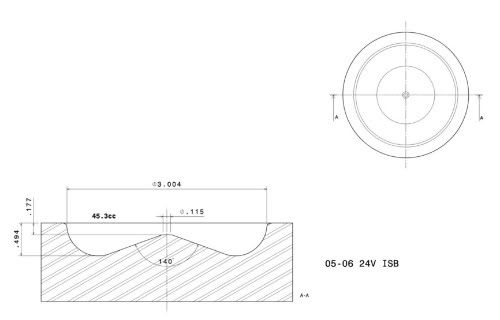

- CR pistons flycut (depth depending on cam)

- 1 more 12V rod. shot peened. balanced. polished,…again

- Custom grind cam (something like 208/220 unknown lift and lsa right now)

- new bearings

- Air Dog II 200 GPH

- 5x.025 injectors. vco style. no filters. pintle lift. dual feed. 260 bar. 155 degree spray angle.

- new cummins head gasket

- check the head for problems

- bench pump (again)

- check the crank. then shotpeened, balanced, polished, …again

- no girdle

Couple things I'm debating though, is what turbo to go to. I want to get something along the lines of an S475/87/1.0 T4. I want to make more power, now that I've had a taste. BTW, some of the parts I'm taking out of the motor are salvageable. I am not planning on using some of them in this particular motor, however…..they're for something else I have up my sleeve…..

I DO NOT care about street drivability (I still don't want to try and drive with a 88 or 105 mm turbo though haha), but I want it to be "possible" to drive on the street.

I am not going with a 6.7 block either. Too much money and hassle for minimal gains.

This question is kinda silly too, but I kinda wanted to hear some votes for either Schaffers or Brad Penn lubricants

ANY input is greatly appreciated. I want to have a SOLID bottom end, and one that can help me make more power in conjunction with the other parts (ie: pistons-injectors-pump-turbo)

Thanks for your time fellas

- 12V block. honed, decked, tapped for 14 mm mains

- arp 14 mm mains

- arp 12 mm 625 head studs

- CR pistons flycut (depth depending on cam)

- 1 more 12V rod. shot peened. balanced. polished,…again

- Custom grind cam (something like 208/220 unknown lift and lsa right now)

- new bearings

- Air Dog II 200 GPH

- 5x.025 injectors. vco style. no filters. pintle lift. dual feed. 260 bar. 155 degree spray angle.

- new cummins head gasket

- check the head for problems

- bench pump (again)

- check the crank. then shotpeened, balanced, polished, …again

- no girdle

Couple things I'm debating though, is what turbo to go to. I want to get something along the lines of an S475/87/1.0 T4. I want to make more power, now that I've had a taste. BTW, some of the parts I'm taking out of the motor are salvageable. I am not planning on using some of them in this particular motor, however…..they're for something else I have up my sleeve…..

I DO NOT care about street drivability (I still don't want to try and drive with a 88 or 105 mm turbo though haha), but I want it to be "possible" to drive on the street.

I am not going with a 6.7 block either. Too much money and hassle for minimal gains.

This question is kinda silly too, but I kinda wanted to hear some votes for either Schaffers or Brad Penn lubricants

ANY input is greatly appreciated. I want to have a SOLID bottom end, and one that can help me make more power in conjunction with the other parts (ie: pistons-injectors-pump-turbo)

Thanks for your time fellas