Truck is back together, drove it home tonight. It freakin feels GOOD! 10psi seems to build a good 200rpms sooner and it climbs from there even faster than before. My original stock lift pump must have definitely been worn out. I put in a genuine Cummins replacement with a comp cam spring, I didn't change any of my AFC settings and I'm putting out a decent amount more smoke. Gonna need to tune it back.

I do have quite a bit of blowby. Even more than before. But I guess that could be expected until the rings seat?

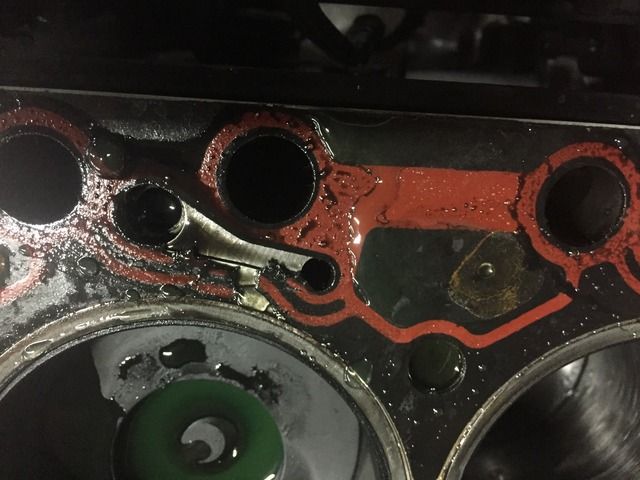

I got a pretty bad oil leak from the bottom of my stock tappet cover after my first pull. I had let the truck run and idle and get up to temp before hooking everything up to make sure there were no leaks... so I don't know if the oil just hadn't been primed enough and hadn't started pooling around the lifters in order to leak out the side, or if the blowby pushed out the seal? I can see exactly where the seal isn't sandwhiched under the cover, I thought I was careful about making sure the seal was seated but maybe I missed it? I have capped off and welded the crank case vent in the tappet cover. I had the oil fill cap on and tight. I have a 1/2" copper line from 4th valve cover that runs down to the exhaust to form a Venturi type setup. Is it possible I just built up too much pressure and if pushed it out?

Other strange occurrence is my transmission was starting in 2nd from a stop since about half way home. Recent changes to the transmission include V8 governor weights and springs, upgraded Billet governor valve, raised line pressure, lowered Throttle cable stop. I think I might be 1-1/2 quarts low on fluid, but I don't think that would cause it.