Redrider2911

New member

- Joined

- Nov 19, 2015

- Messages

- 780

Thanks for the compliments guys.

June 18th 2016

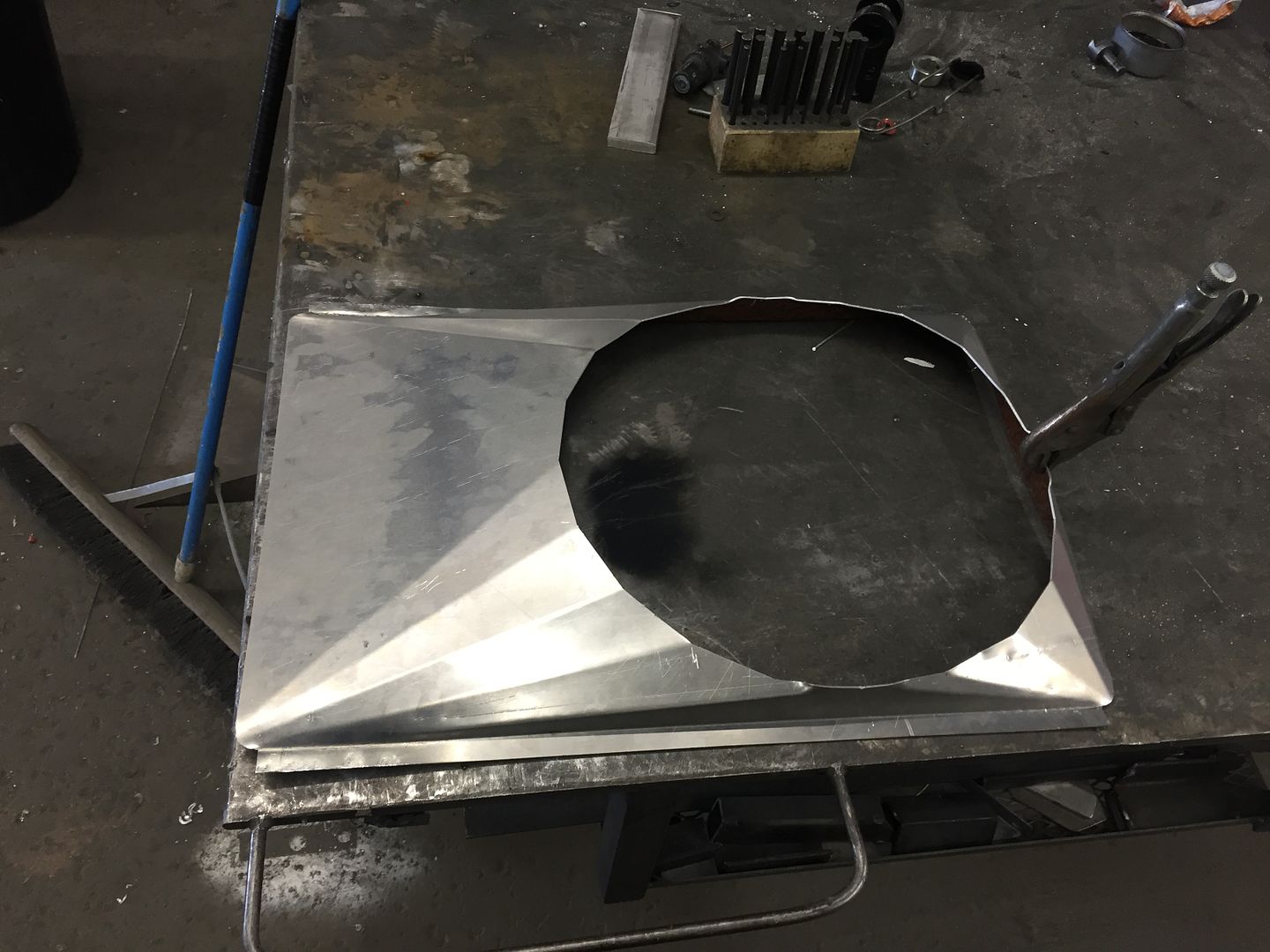

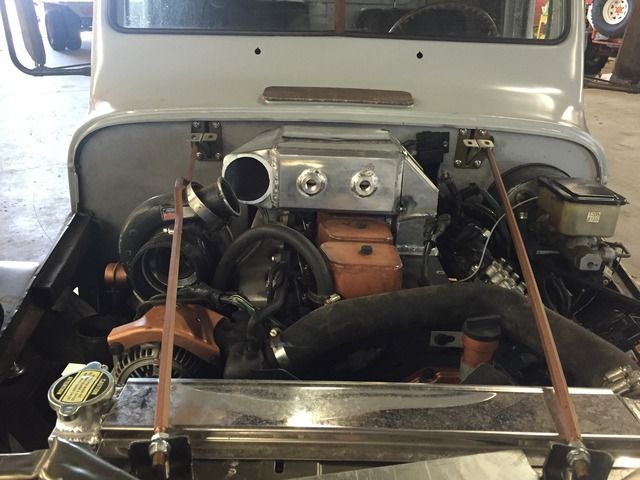

Intake side all welded together and tacked to the core. I think it's gonna look pretty cool after I use some scotchbrite to dull the shine.

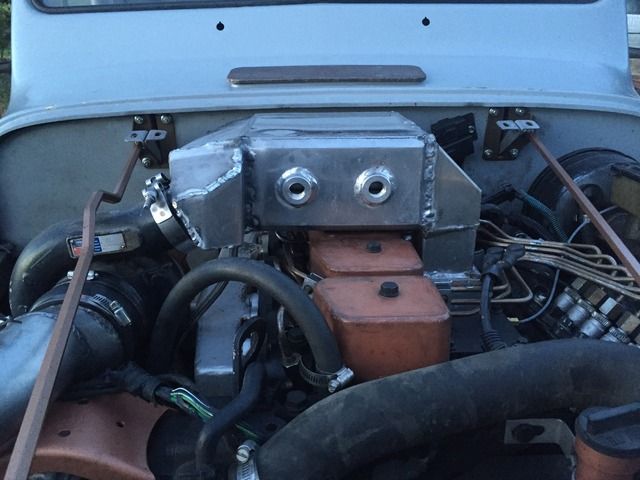

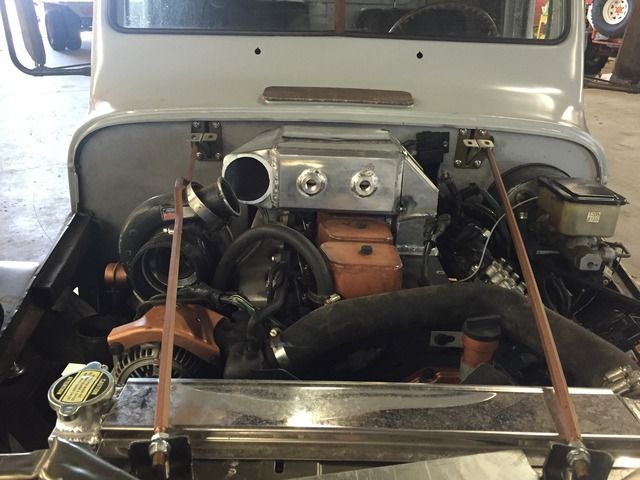

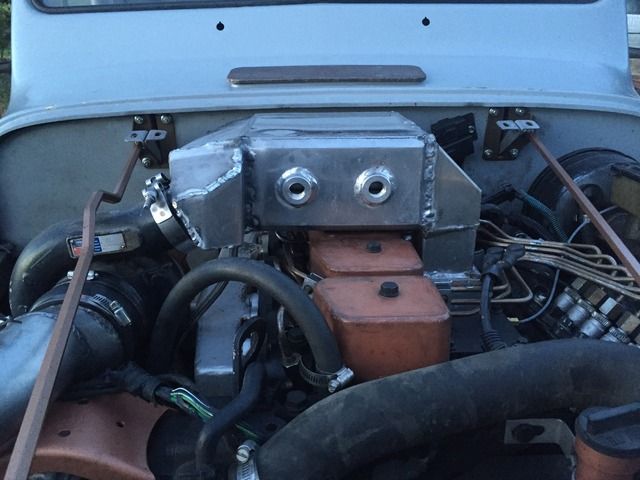

What she ended up looking like. Seems to be working good. I can actually notice a big difference on the first pull after start up. The intercooler is just acting like a giant heat sink right now. After the first pull it has hardly any power because now it is heat soaked. Can't wait to get some water running through it to keep it cool.

June 18th 2016

Intake side all welded together and tacked to the core. I think it's gonna look pretty cool after I use some scotchbrite to dull the shine.

What she ended up looking like. Seems to be working good. I can actually notice a big difference on the first pull after start up. The intercooler is just acting like a giant heat sink right now. After the first pull it has hardly any power because now it is heat soaked. Can't wait to get some water running through it to keep it cool.